- Victory

- China

- Quantity(Tons) 1 - 10 11 - 40 41 - 100 >100 Est. Time(days) 5 7 15 To be negotiated

- 2000T/Month

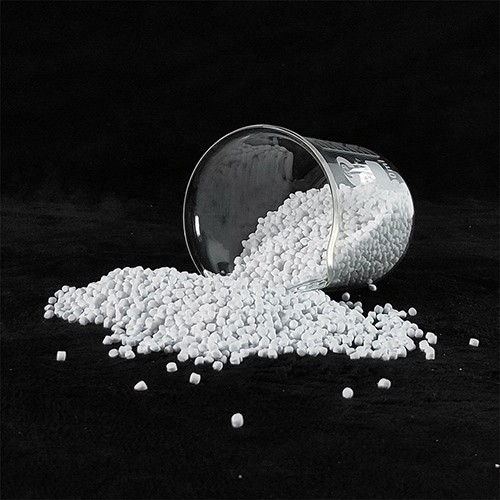

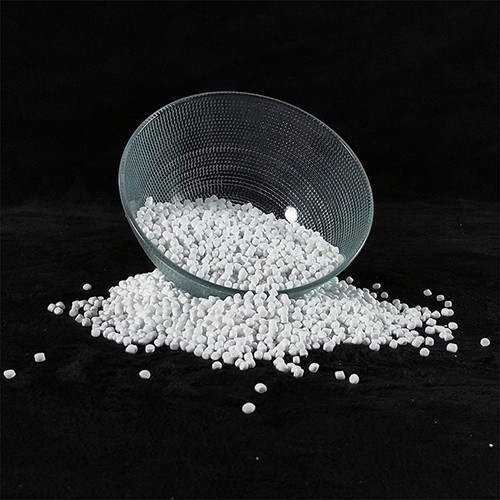

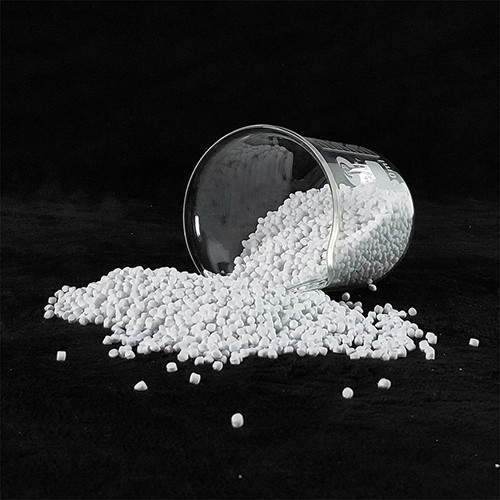

1.Talc Filler Masterbatch For Blowing Film, stable chemical performance, strong hiding power, can prevent the paint coating aging rupture and improve the ability of resistance to weathering.

2.In ceramics, Talc Filler Masterbatch For Blowing Film allows firing temperatures to be reduced and also gives ceramics better thermal expansion.

3.In rubber, Talc Filler Masterbatch For Blowing Film improves UV radiation resistance and improves molding ability.

4.Talc Filler Masterbatch For Blowing Film an improve the toughness of the product.

5.Talc Filler Masterbatch For Blowing Film, as a main inorganic filler, can be added to epoxy resin, especially in CCL( copper-clad plate ) industry, which can improve its drilling property, rigidity and toughness.

The advantages of PE Talc Filler Masterbatch are mainly reflected in the following aspects:

PE Talc Filler Masterbatch can Improve material rigidity and hardness: The flake structure of Talc Powder Filler Masterbatch enables it to effectively enhance the rigidity and hardness of plastics and other materials, and improve the strength and impact resistance of materials.

PE Talc Filler Masterbatch can Improve dimensional stability: Talc Powder Filler Masterbatch can reduce the thermal expansion and contraction of products, enhance the dimensional stability of materials.Talc Powder Filler Masterbatch can reduce the possibility of deformation during processing and use.

Talc Powder Filler Masterbatch can Reduce production costs: As a cheap mineral filler, Talc Powder Filler Masterbatch can reduce the need for expensive resins or other materials, thus significantly reducing production costs, especially in mass production.

Talc Powder for Plastic Filler Masterbatch can Enhanced heat resistance: PE Talc Filler Masterbatch has good high-temperature resistance. Adding talc powder masterbatch can improve the heat resistance of the material, making the product more stable in high-temperature environments.

Talc Powder for Plastic Filler Masterbatch can Improve processing performance: PE Talc Filler Masterbatch can improve the fluidity and processing performance of materials, making injection molding, extrusion and other processing processes smoother, reducing energy consumption and improving production efficiency.

Talc Powder for Plastic Filler Masterbatch can Improve surface quality: The fine particles of PE Talc Filler Masterbatch can make the surface of the product smoother and flatter, improve the appearance quality of the material, and provide a better touch.

Talc Powder for Plastic Filler Masterbatch can Improve flame retardancy: Talc powder masterbatch contains non-flammable components, which can improve the flame retardancy of the material to a certain extent, especially suitable for occasions with high flame retardant requirements.

Good dispersion: The talc powder masterbatch has been specially treated and has good dispersion. It can be evenly distributed in the matrix material without agglomeration or stratification, ensuring the uniform performance of the material.

These advantages make talc masterbatch widely used in plastics, rubber, coatings and other industries, especially in improving performance and reducing costs. It has obvious competitive advantages.

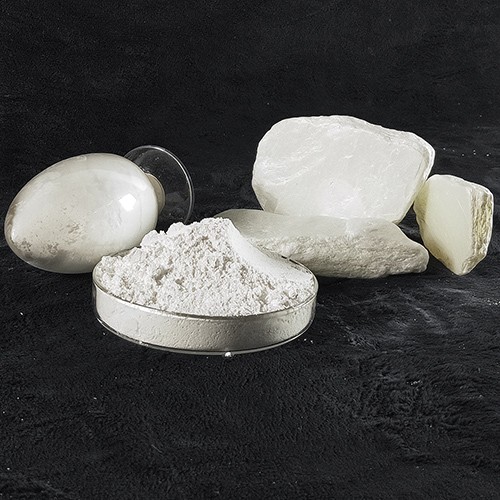

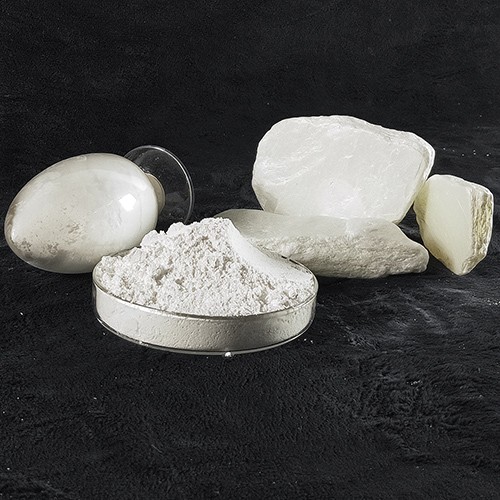

General Purpose Talc GENERIC® FUSE®

GENERIC® makes use of the inherent characteristics of talc, such as high whiteness, a plate-like crystal shape, and chemical resistance, and has a wide range of applications, including those for general-purpose resin, functional resin, electrical materials (e.g., resist ink and adhesive), and automotive paints.

| Test Item | ||||||

| Product | Whiteness (%) Hunter method | Particle size D50 (μm) Laser diffraction | Moisture content (%) JIS K 5101 | Apparent density (g/ml) JIS K 5101 | Specific surface area (㎡/g) BET method | Oil absorption (ml/100g) JIS K 5101 |

| GP-3C | 96 | 2.8 | 0.2 | 0.12 | 12.0 | 45 |

| GL-2C | 96 | 4.0 | 0.2 | 0.13 | 10.5 | 44 |

| GP-OG-5 | 96 | 5.0 | 0.2 | 0.15 | 8.0 | 40 |

| GP-OG-7 | 96 | 7.0 | 0.2 | 0.18 | 7.5 | 36 |

| G-1C | 90 | 5.0 | 0.2 | 0.15 | 9.0 | 40 |

| GK-1CB | 94 | 8.0 | 0.2 | 0.25 | 7.0 | 35 |

FUSE® is used for blended fillers in a wide range of fields, including the plastic, paper, rubber, paints, and ceramic application fields.

| Test Item | |||||||

| Product | Whiteness (%) Hunter method | Particle size D50 (μm) Laser diffraction | 45μm residue (%) JIS K 5101 | Moisture content (%) JIS K 5101 | Apparent density (g/ml) JIS K 5101 | Specific surface area (㎡/g) BET method | Oil absorption (ml/100g) JIS K 5101 |

| F94-3 | 94 | 14 | 0.2 | 0.3 | 0.35 | 4. | 26 |

| F92-5 | 93 | 15 | 0.2 | 0.2 | 0.4 | 4.0 | 25 |

| F90-7 | 88 | 17 | 0.2 | 0.2 | 0.4 | 3.5 | 24 |

| F83-8 | 83 | 17 | 0.2 | 0.2 | 0.4 | 3.5 | 24 |

| F80-12 | 80 | 12 | 0.3 | 0.3 | 0.4 | 4.5 | 28 |

| F90-3 | 91 | 14 | 0.2 | 0.2 | 0.3 | 5.0 | 26 |

| F94-7 | 94 | 18 | 0.5 | 0.2 | 0.35 | 5.5 | 23 |

Company Introduction:

Founded in 2019, the comapmy is a global supplier of halogen-free flame retardant material and Nonmetallic ultrafine nano-powder.

We are a comprehensive company intergrating R&D, productoion and sales, have more than 200 employees and opreate oversea, producing in own mines, serving more than hundred customers including the world’s top 500 enterprises in Europe, Japan, South Korea and Sourheast Asia.

we are committed to providing for domestic and foreign customers with high quality and high technology products and services in related application industries.