- Victory

- China

- Quantity(Tons) 1 - 10 11 - 40 41 - 100 >100 Est. Time(days) 5 7 15 To be negotiated

- 2000T/Month

1. The Talc powder for Filler Masterbatch, Packaging Type we produce has high dimensional stability and chemical stability.

2. The Food Grade Talc Powder Filler we produce can improve stability and reduce the thermal expansion, contraction, warping and other properties of the object.

3. The Talc Base Filler Masterbatch we produce is widely used in automobiles, electrical materials and other fields.

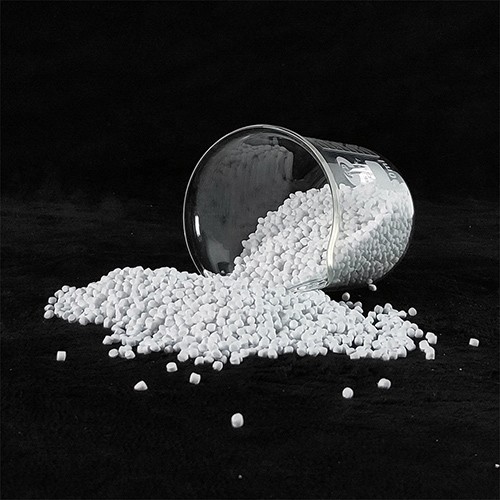

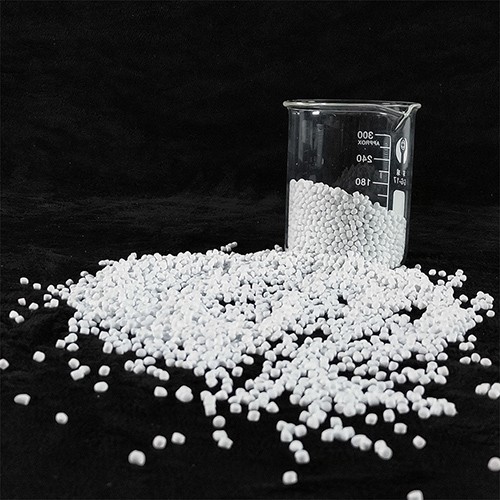

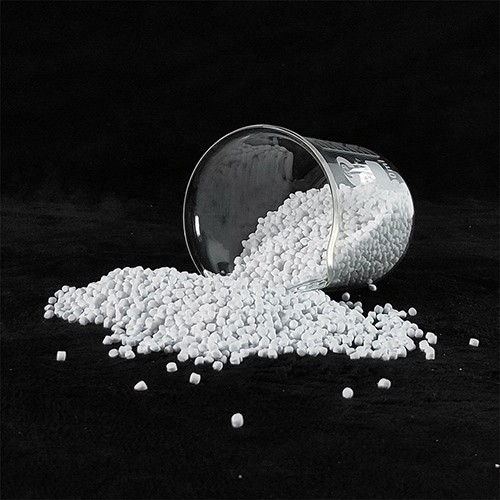

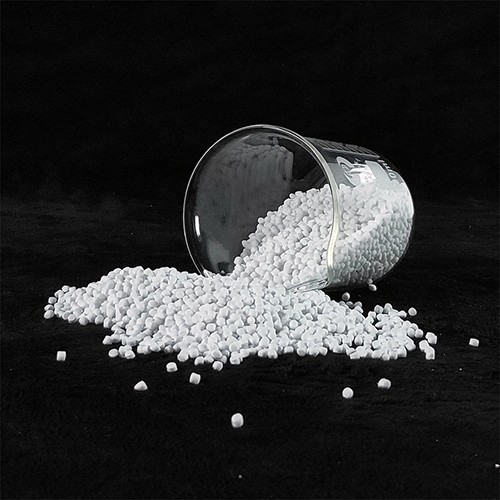

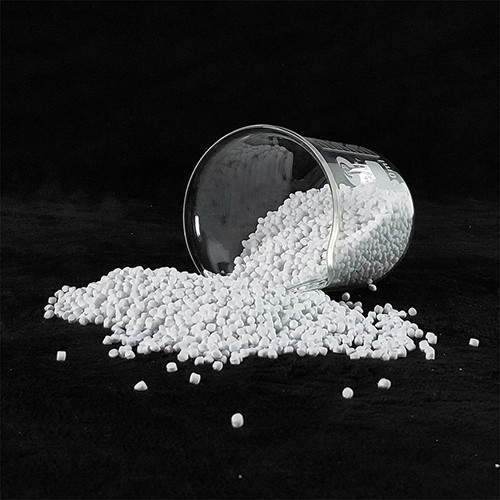

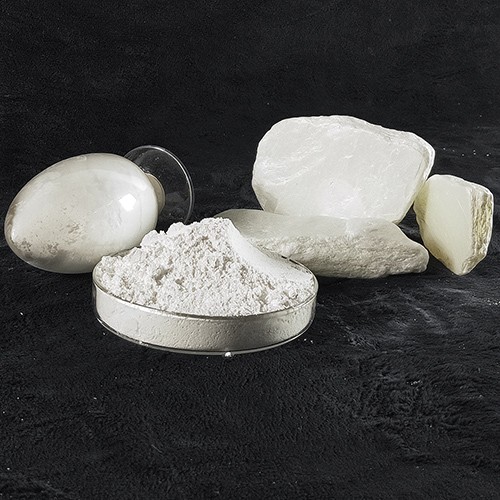

Product Introduction of Talc Base Filler Masterbatch:

Our talc master batch is a strictly screened and processed ultra-fine natural mineral powder, mainly composed of magnesium silicate, which is widely used in the food processing industry. Food grade talc powder filler is mainly used as an anti-caking agent, filler and dispersant, which can improve the fluidity and texture of the product and extend the shelf life. Our talc in plastic modification has been strictly tested and meets international food grade standards. It has passed ISO 9001 and other certifications, meets food safety regulations, and is suitable for all types of food processing companies. Using our food grade talc powder filler can not only ensure the quality and safety of food, but also improve the appearance and taste of the product.

Product Advantages of Talc Master Batch:

The talc in plastic modification we produce has the characteristics of high purity, ultra-fine particle size, high stability, non-toxicity, tastelessness and strong water absorption, ensuring excellent filling effect without affecting the taste of food, and stable chemical properties, suitable for various processing environments. The talc master batch we produce is widely used in candy, flour, seasoning powder, milk powder, infant food and other processed foods. It can prevent candy from sticking, improve the uniformity and fluidity of powdered materials, especially when used as an additive in food, it can improve the texture and ensure uniform distribution of ingredients.

Application of Talc powder for Filler Masterbatch:

The talc in plastic modification we produce can significantly improve the physical properties of woven bags, and significantly improve the service life and long-term safety of the products. When producing round wire products, adding an appropriate amount of talc base filler masterbatch can achieve satisfactory results. For example, adding 5% to 10% talc master batch to the mesh can effectively reduce the entanglement and adhesion of the mesh, improve the visual effect of the fishing net in the water, and improve the fishing efficiency without affecting the transparency of the net.

In recent years, the home appliance industry has developed rapidly. According to relevant data, 60%-80% of home appliances are made of plastic parts. The talc powder for filler masterbatch we produce can not only reduce the production cost of home appliances, but also improve the grade and appearance of home appliances.

General Purpose of Talc Base Filler Masterbatch GENERIC® FUSE®

Talc Base Filler Masterbatch | Test Item | |||||

Whiteness (%) | Particle size | Moisture | Apparent | Specific | Oil absorption (ml/100g) | |

GP-3C | 96 | 2.8 | 0.2 | 0.12 | 12.0 | 45 |

GL-2C | 96 | 4.0 | 0.2 | 0.13 | 10.5 | 44 |

GP-OG-5 | 96 | 5.0 | 0.2 | 0.15 | 8.0 | 40 |

GP-OG-7 | 96 | 7.0 | 0.2 | 0.18 | 7.5 | 36 |

G-1C | 90 | 5.0 | 0.2 | 0.15 | 9.0 | 40 |

GK-1CB | 94 | 8.0 | 0.2 | 0.25 | 7.0 | 35 |

FUSE® is used for blended fillers in a wide range of fields, including the plastic, paper, rubber, paints, and ceramic application fields.

Talc in Plastic Modification | Test Item | ||||||

Whiteness (%) | Particle size | 45μm residue (%) | Moisture | Apparent | Specific | Oil absorption (ml/100g) | |

F94-3 | 94 | 14 | 0.2 | 0.3 | 0.35 | 4.0 | 26 |

F92-5 | 93 | 15 | 0.2 | 0.2 | 0.40 | 4.0 | 25 |

F90-7 | 88 | 17 | 0.2 | 0.2 | 0.40 | 3.5 | 24 |

F83-8 | 83 | 8 | 0.1 | 0.3 | 0.30 | 10.0 | 35 |

F80-12 | 80 | 12 | 0.3 | 0.3 | 0.40 | 4.5 | 28 |

F90-3 | 91 | 14 | 0.2 | 0.2 | 0.30 | 5.0 | 26 |

F94-7 | 94 | 18 | 0.5 | 0.2 | 0.35 | 5.5 | 23 |

Company Introduction:

LIAONING VICTORY FIRE-RETARDANT MATERIAL TECHNOLOGY CO.,LTD. is a research and development, production and sales of integrated company mainly operate inorganic fire retardant and non-metallic mineral products such as food grade talc powder filler and talc master batch. We provide a range of shipping options, including sea, air, rail, and express delivery. With over a decade of expertise in non-metallic mineral processing, we offer complete customer support from initial consultation through to final order fulfillment. Our team is dedicated to delivering enthusiastic service and taking full responsibility for every project. Your satisfaction is our highest priority, and we aim to build lasting relationships with each client. As our business continues to grow globally, we look forward to collaborating with you in the future.