- Victory

- China

- Quantity(Tons) 1 - 10 11 - 40 41 - 100 >100 Est. Time(days) 5 7 15 To be negotiated

- 2000T/Month

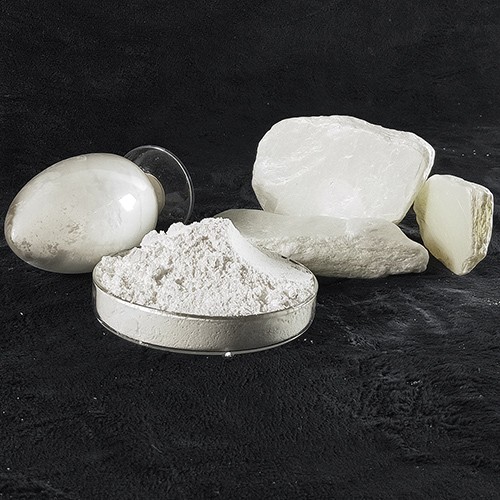

1. The talc masterbatch filler we produce can whiten plastics and is an excellent filler.

2. The talc masterbatch filler we produce has stable chemical properties and strong hiding power, which can prevent the paint coating from aging and cracking.

3. The talc masterbatch filler we produce has excellent physical and chemical properties such as lubricity, fire resistance, and strong acid resistance.

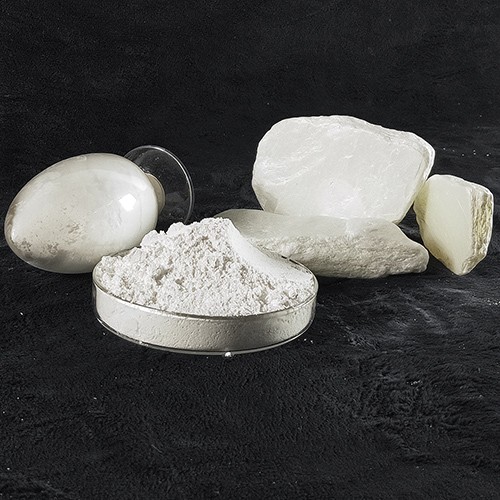

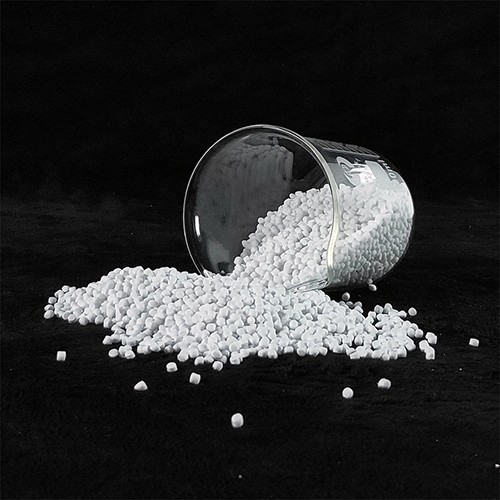

Product Introduction Of Talc Masterbatch Filler:

The talc masterbatch filler we produce is an important additive, modifier and filler widely used in the chemical industry. Especially in the modification applications of plastics and rubber, talc masterbatch filler shows significant enhancement effects. As the main advantage of talc masterbatch filler, talc masterbatch filler can significantly improve the tensile strength, impact performance, creep resistance, heat resistance and tear resistance of plastic products, thereby improving the overall performance of the product. In addition, talc powder also has the ability to improve the appearance of products, effectively reduce shrinkage, enhance barrier effects and reduce breathability.

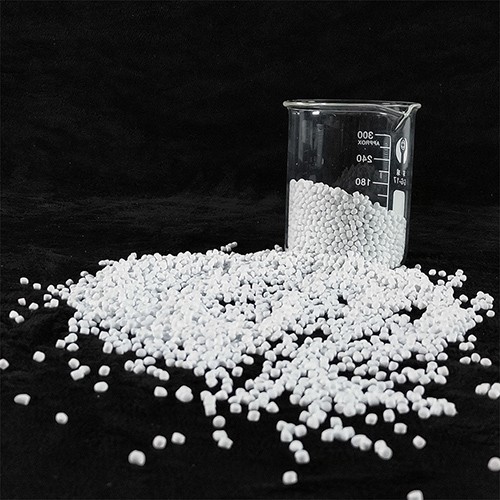

Product Advantages Of Filler Masterbatch:

As a high-quality additive, filler masterbatch has several significant advantages, making filler masterbatch indispensable in the chemical and plastics industries. Filler masterbatch can significantly improve the tensile strength, impact performance and heat resistance of plastic products and enhance their durability. At the same time, filler masterbatch effectively reduces breathability, improves barrier effect, and improves moisture resistance. In addition, rubber product filler masterbatch can also reduce the shrinkage of products, improve the smoothness of appearance, and increase rigidity and stiffness. Taken together, talc filler masterbatch not only optimizes the physical properties of the product, but also brings good economic benefits to the company. Talc filler masterbatch is an ideal modification and filling material in the plastics and rubber industry.

Application Of Filler Masterbatch For Plastics In Cosmetics Industry:

Filler masterbatch for plastics is increasingly used in the cosmetics industry and has become an important tool to improve product quality and performance. By adding talc filler masterbatch to plastic packaging and containers, filler masterbatch for plastics not only significantly reduces production costs, but also improves the physical properties of the material. Talc filler masterbatch helps improve the rigidity, impact resistance and heat resistance of plastics, ensuring the safety of cosmetic packaging during transportation and use. At the same time, this filler masterbatch for plastics can also optimize the appearance of the product, making the packaging smoother and brighter, and improving the visual experience of consumers. With the focus on environmental protection and sustainable development, the application of filler masterbatch for plastics also provides a more environmentally friendly solution for the cosmetics industry and helps achieve green production. In short, the application of filler masterbatch for plastics in the cosmetics industry not only improves product performance, but also enhances market competitiveness.

Rubber Product Filler Masterbatch Can Be Widely Used In PP, PE, PS, PA, ABS, PC, PVC and other resins.

Rubber Product Filler masterbatch | Test Item | |||||

Whiteness (%) | Particle size | Moisture | Apparent | Specific | Oil absorption (ml/100g) | |

GP-3C | 96 | 2.8 | 0.2 | 0.12 | 12.0 | 45 |

GL-2C | 96 | 4.0 | 0.2 | 0.13 | 10.5 | 44 |

GP-OG-5 | 96 | 5.0 | 0.2 | 0.15 | 8.0 | 40 |

GP-OG-7 | 96 | 7.0 | 0.2 | 0.18 | 7.5 | 36 |

G-1C | 90 | 5.0 | 0.2 | 0.15 | 9.0 | 40 |

GK-1CB | 94 | 8.0 | 0.2 | 0.25 | 7.0 | 35 |

Rubber Product Filler Masterbatch Is Used For Blended Fillers In A Wide Range Of Fields, Including The Plastic, Paper, Rubber, Paints, And Ceramic Application Fields.

Rubber Product Filler Masterbatch | Test Item | ||||||

Whiteness (%) Hunter Method | Particle Size D50 (Μm) Laser Diffraction | 45μm Residue (%) Jis K 5101 | Moisture | Apparent | Specific | Oil absorption (ml/100g) | |

F94-3 | 94 | 14 | 0.2 | 0.3 | 0.35 | 4.0 | 26 |

F92-5 | 93 | 15 | 0.2 | 0.2 | 0.40 | 4.0 | 25 |

F90-7 | 88 | 17 | 0.2 | 0.2 | 0.40 | 3.5 | 24 |

F83-8 | 83 | 8 | 0.1 | 0.3 | 0.30 | 10.0 | 35 |

F80-12 | 80 | 12 | 0.3 | 0.3 | 0.40 | 4.5 | 28 |

F90-3 | 91 | 14 | 0.2 | 0.2 | 0.30 | 5.0 | 26 |

F94-7 | 94 | 18 | 0.5 | 0.2 | 0.35 | 5.5 | 23 |

Quality Certifications For Rubber Product Rubber Product Filler Masterbatch:

Our company has successfully passed the iso9001 quality system certification, ensuring that our production and sales activities strictly comply with international standards. Our talc filler masterbatch also complies with multiple international certification standards such as sgs, reach and rohs, demonstrating our high attention to the quality and safety of talc filler masterbatch. With rich industry experience and advanced r&d and production technology, we not only ensure the quality of talc filler masterbatch, but also continuously improve the environmental benefits of talc filler masterbatch. These efforts have not only won the trust and support of our customers, but also demonstrated our strength and sense of responsibility as an industry leader. We will continue to be committed to providing high-quality talc filler masterbatch to meet the needs of global customers.

About Us:

Liaoning Victory Fire-retardant Material Technology Co., Ltd. is a comprehensive enterprise focusing on the research and development, production and sales of inorganic flame retardants and non-metallic mineral products. We provide a variety of transportation options, including sea, air, rail and express delivery, to ensure that customers enjoy a higher cost-effective logistics. With more than ten years of experience in fine processing of non-metallic minerals, we provide customers with a full range of services from consultation to final delivery. We always treat every customer with enthusiasm and responsibility, committed to building a solid cooperative relationship, and customer satisfaction is our primary goal. As our business expands globally, we look forward to working with you to create a better future.