- Victory

- China

- Quantity(Tons) 1 - 10 11 - 40 41 - 100 >100 Est. Time(days) 5 7 15 To be negotiated

- 2000T/Month

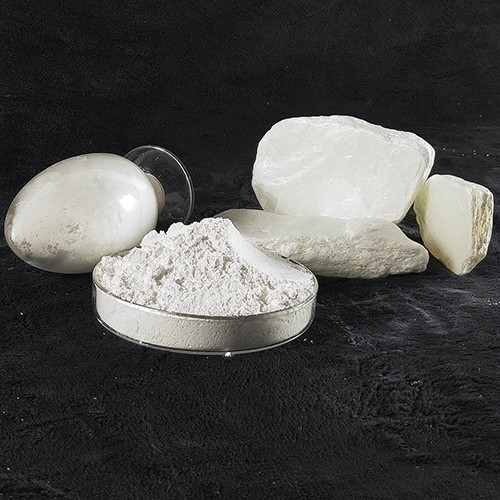

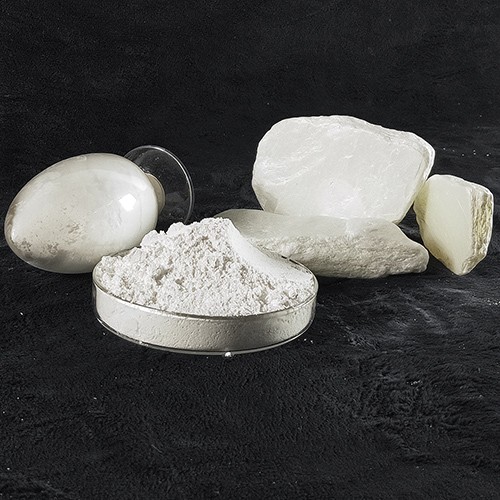

1. PE masterbatch for blowing bag is a very important filler in polypropylene plastics, with low relative density and low price.

2.The filler masterbatch for film we produce can improve dimensional stability and reduce thermal expansion, contraction, warping and other properties.

3.The talc filler masterbatch for blowing film we produce can be added to food packaging plastics, especially lunch boxes, plates, tableware, etc.

Product Introduction of Filler Masterbatch For Film:

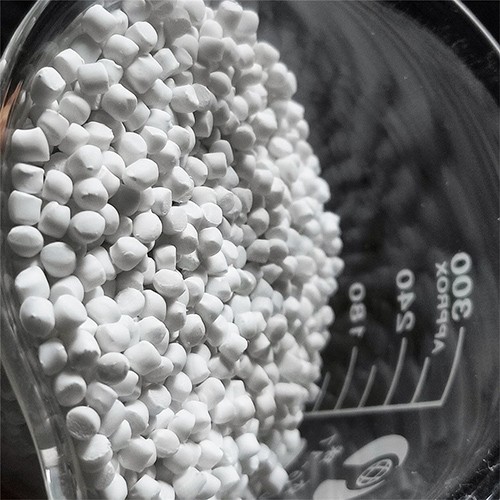

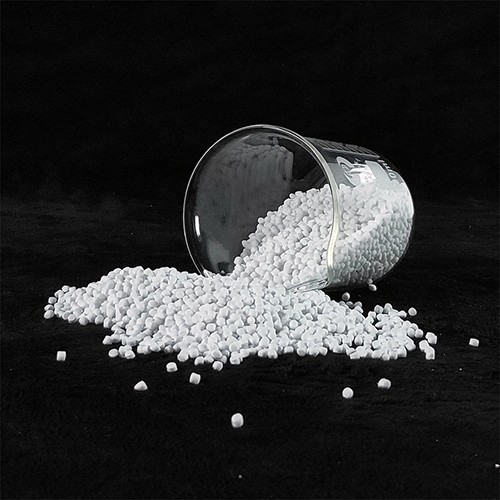

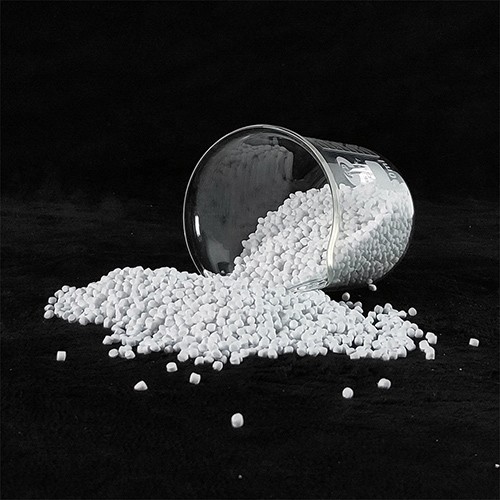

PE Masterbatch For Blowing Bag is a highly efficient additive designed for plastic film and film blowing process, and is widely used in the manufacture of various types of plastic bags. PE filler masterbatch for PE blown film optimizes the performance of polyethylene materials, improves the transparency, flexibility and mechanical strength of the film, and enhances the tear resistance and puncture resistance of the material. PE filler masterbatch for pe blown film has good dispersibility and can be evenly mixed into the base material to ensure that the product has excellent processing performance during the film blowing process.

Talc filler masterbatch for blowing film can also customize different colors, glossiness and functional additives according to needs to meet the specific requirements of different customers for packaging materials. At the same time, filler masterbatch for film has environmentally friendly characteristics and meets international standards. It is suitable for occasions with high safety requirements such as food packaging.

Product Advantages of PE Masterbatch For Blowing Bag:

1. The PE filler masterbatch for PE blown film we produce can improve the tear resistance, puncture resistance and flexibility of the film, making the plastic bag tougher and more durable.

2. The talc filler masterbatch for blowing film we produce can be evenly distributed in the substrate, and will not produce color difference and impurities during the film blowing process.

3. The filler masterbatch for film we produce has good optical effects, which can improve the transparency and glossiness of the film, making the product appearance more beautiful.

Specific Parameters of PE Filler Masterbatch For PE Blown Film GENERIC® FUSE®:

Product | Test Item | |||||

Whiteness (%) | Particle size | Moisture | Apparent | Specific | Oil absorption (ml/100g) | |

GP-3C | 96 | 2.8 | 0.2 | 0.12 | 12.0 | 45 |

GL-2C | 96 | 4.0 | 0.2 | 0.13 | 10.5 | 44 |

GP-OG-5 | 96 | 5.0 | 0.2 | 0.15 | 8.0 | 40 |

GP-OG-7 | 96 | 7.0 | 0.2 | 0.18 | 7.5 | 36 |

G-1C | 90 | 5.0 | 0.2 | 0.15 | 9.0 | 40 |

GK-1CB | 94 | 8.0 | 0.2 | 0.25 | 7.0 | 35 |

PE masterbatch for blowing bag is used for blended fillers in a wide range of fields, including the plastic, paper, rubber, paints, and ceramic application fields.

Product | Test Item | ||||||

Whiteness (%) | Particle size | 45μm residue (%) | Moisture | Apparent | Specific | Oil absorption (ml/100g) | |

F94-3 | 94 | 14 | 0.2 | 0.3 | 0.35 | 4.0 | 26 |

F92-5 | 93 | 15 | 0.2 | 0.2 | 0.40 | 4.0 | 25 |

F90-7 | 88 | 17 | 0.2 | 0.2 | 0.40 | 3.5 | 24 |

F83-8 | 83 | 8 | 0.1 | 0.3 | 0.30 | 10.0 | 35 |

F80-12 | 80 | 12 | 0.3 | 0.3 | 0.40 | 4.5 | 28 |

F90-3 | 91 | 14 | 0.2 | 0.2 | 0.30 | 5.0 | 26 |

F94-7 | 94 | 18 | 0.5 | 0.2 | 0.35 | 5.5 | 23 |

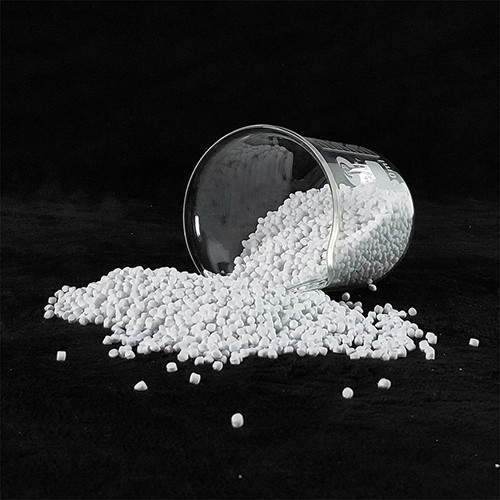

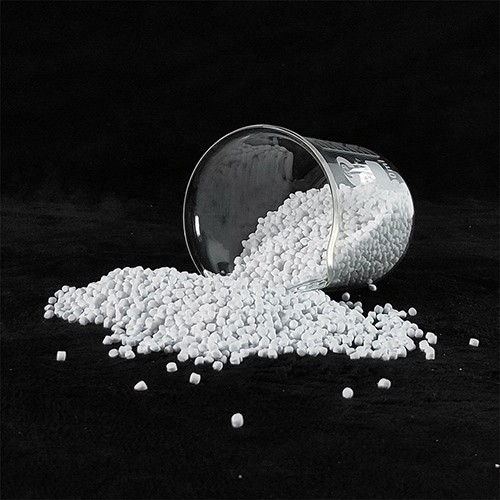

Package and Delivery of Talc Filler Masterbatch For Blowing Film:

We can offer higher cost performance in cargo transportation and multiple transportation methods could be selected by customers, including Shipping, Air Transport, Rail Transport and Courier Transport. The PE masterbatch for blowing bag is packed in 25kg PP bags or paper bags, and can also be packed in 500-1000kg ton bags and equipped with pallets. Please keep it in a dry and cool environment when storing. It can be stored stably for up to 5 years at room temperature.

Company Introduction:

LIAONING VICTORY FIRE-RETARDANT MATERIAL TECHNOLOGY CO.,LTD. is a research and development, production and sales of integrated company mainly operate inorganic fire retardant and non-metallic mineral products. Our main productus contain Talc products, environmental flame retardants, filler masterbatch for film and other non-metallic materials. We have a strict quality management system and have passed ISO9001 quality system certification. The PE masterbatch for blowing bag we produce have all been strictly tested by the quality inspection department, and the product quality is excellent. With more ten years experience in fine machining of non-metallic minerals, We provide comprehensive customer service from the initial consultation to the final delivery of your order.