- Victory

- China

- Quantity(Tons) 1 - 10 11 - 40 41 - 100 >100 Est. Time(days) 5 7 15 To be negotiated

- 2000T/Month

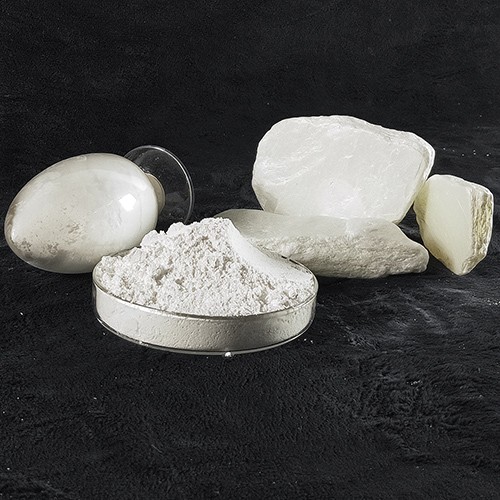

1.Talc powder has the advantages of small relative density, low price, good processing and good comprehensive performance.

2.Talc powder can thin and reduce weight.

3.Talc powder is widely used in cosmetic products such as baby powder and adult body and facial powders, as well as in a number of other consumer products.

4.Talcum powder can also be mixed with a powder or bronzer that is a bit too dark to lighten it up.

5.Talcum powder can work like a moisturiser to help soothe extra-dry skin. If you have areas of irritated skin, rub a bit of talcum powder in to calm it.

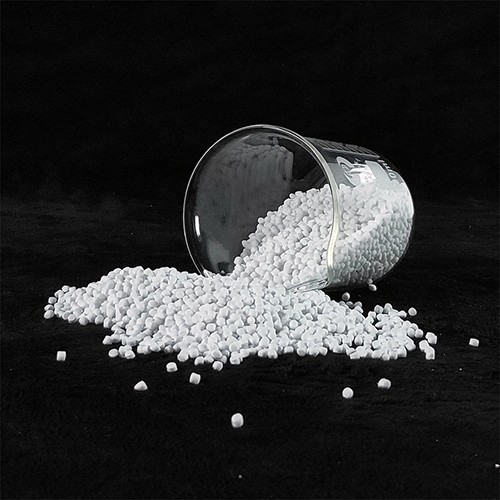

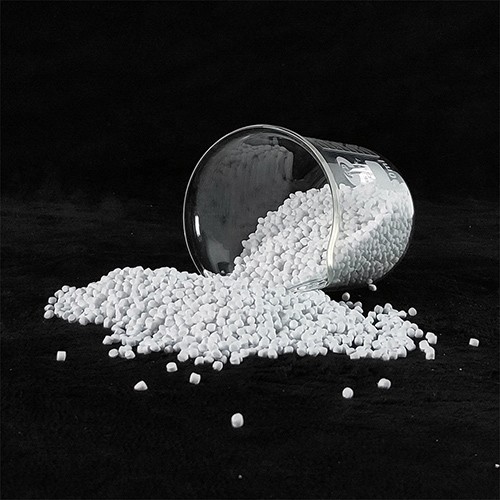

Carrier Free Talcum Powder Filled Masterbatch has the following advantages as filler in plastics, rubber, coatings and other industries:

Talc Powder can Improve rigidity and hardness: Talcum powder has a flaky structure.Talcum powder can significantly improve the rigidity and hardness of plastics and other materials, making the product more resistant to deformation.

Talc Powder can Improve dimensional stability: Talc masterbatch can reduce the thermal expansion and contraction of plastic products.Talcum powder can increase the dimensional stability of products, and reduce product deformation during processing or use.

Talc Powder can Reducing costs: As a cheap mineral filler, Talc masterbatch can replace some expensive resin materials, thereby reducing production costs, and is especially suitable for mass production applications.

Talc masterbatch can Improved processing performance: After adding talc masterbatch, the processing properties such as fluidity and anti-stickiness of the material can be improved, making the injection molding and extrusion process easier to control and operate.

Talc masterbatch can Improve heat resistance:Talc masterbatch has good heat resistance.Talc masterbatch can increase the high temperature resistance of plastic products and extend their service life.

Talc Powder can Improve surface smoothness and texture: The flaky particles of talc powder can fill the tiny gaps in the material.Talcum powder can increase the flatness and smoothness of the product surface, and improve the appearance quality.

Talc Powder has Good dispersion: After treatment, the talc powder particles in the talc powder masterbatch have good dispersibility and can be evenly distributed in the matrix material without agglomeration or agglomeration.

Talc Powder can Improve flame retardant properties: Talcum powder itself is not easy to burn. As a filler, Talcum powder can improve the flame retardant properties of plastics and other materials to a certain extent.

These advantages make talc masterbatch widely used in many industries, especially playing an important role in plastic products, auto parts, home appliance casings and other fields.

General Purpose Talc GENERIC® FUSE®

GENERIC® makes use of the inherent characteristics of talc, such as high whiteness, a plate-like crystal shape, and chemical resistance, and has a wide range of applications, including those for general-purpose resin, functional resin, electrical materials (e.g., resist ink and adhesive), and automotive paints.

| Test Item | ||||||

| Product | Whiteness (%) Hunter method | Particle size D50 (μm) Laser diffraction | Moisture content (%) JIS K 5101 | Apparent density (g/ml) JIS K 5101 | Specific surface area (㎡/g) BET method | Oil absorption (ml/100g) JIS K 5101 |

| GP-3C | 96 | 2.8 | 0.2 | 0.12 | 12.0 | 45 |

| GL-2C | 96 | 4.0 | 0.2 | 0.13 | 10.5 | 44 |

| GP-OG-5 | 96 | 5.0 | 0.2 | 0.15 | 8.0 | 40 |

| GP-OG-7 | 96 | 7.0 | 0.2 | 0.18 | 7.5 | 36 |

| G-1C | 90 | 5.0 | 0.2 | 0.15 | 9.0 | 40 |

| GK-1CB | 94 | 8.0 | 0.2 | 0.25 | 7.0 | 35 |

FUSE® is used for blended fillers in a wide range of fields, including the plastic, paper, rubber, paints, and ceramic application fields.

| Test Item | |||||||

| Product | Whiteness (%) Hunter method | Particle size D50 (μm) Laser diffraction | 45μm residue (%) JIS K 5101 | Moisture content (%) JIS K 5101 | Apparent density (g/ml) JIS K 5101 | Specific surface area (㎡/g) BET method | Oil absorption (ml/100g) JIS K 5101 |

| F94-3 | 94 | 14 | 0.2 | 0.3 | 0.35 | 4.0 | 26 |

| F92-5 | 93 | 15 | 0.2 | 0.2 | 0.4 | 4.0 | 25 |

| F90-7 | 88 | 17 | 0.2 | 0.2 | 0.4 | 3.5 | 24 |

| F83-8 | 83 | 8 | 0.1 | 0.3 | 0.3 | 10 | 35 |

| F80-12 | 80 | 12 | 0.3 | 0.3 | 0.4 | 4.5 | 28 |

| F90-3 | 91 | 14 | 0.2 | 0.2 | 0.3 | 5.0 | 26 |

| F94-7 | 94 | 18 | 0.5 | 0.2 | 0.35 | 5.5 | 23 |

Company Introduction:

Corporate Philosophy: Quality is fundamental, integrity is the foundation.

Corporate Mission: To build a one-stop shopping platform for high-quality functional non-metal products.

Corporate Vision: To be among the top, with a global perspective, and to unleash the infinite potential of non-metal resources.

Core Corporate Values: Customer first, teamwork, unity of knowledge and action, deep contemplation, continuous improvement, and dedication to one's profession.