- Victory

- China

- Quantity(Tons) 1 - 10 11 - 40 41 - 100 >100 Est. Time(days) 5 7 15 To be negotiated

- 2000T/Month

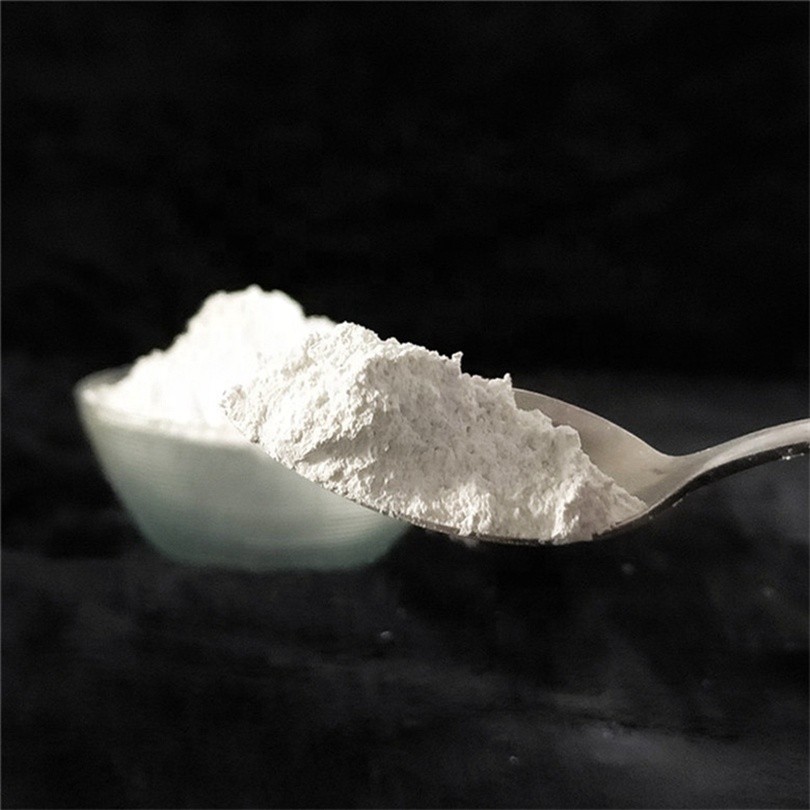

1.High purity calcium carbonate is has natural white and has excellent dispersion.

2.High purity calcium carbonate can mix with polyethylene resin for blow molding, extrusion, etc., is easy to disperse.

3.High purity calcium carbonate has strong covering power and adhesion.

4.High purity calcium carbonate can improve the rheological property of the product and improve its formability.

5.High purity calcium carbonate is pure white granule, which can be prepared flexibly to produce various color products.In case of a large amount of filling, so that the products can still maintain good mechanical properties.Contains antioxidants and anti - aging agent, can prolong the service life of the product.

Calcium Carbonate precipitated masterbatch is a commonly used plastic additive. Its main components are calcium carbonate and carrier resin. It is widely used in the field of plastic processing. Its main uses include:

Carbonate chemistry-Reducing production costs: The price of Calcium Carbonate precipitated masterbatch is relatively low, which can effectively replace some raw material resins and reduce the overall cost of plastic products.

Carbonate chemistry-Improving product performance: The addition of Calcium Carbonate precipitated can increase the rigidity, hardness and heat resistance of plastic products, and help improve the mechanical properties of products.

Carbonate chemistry-Improving processing efficiency: Calcium Carbonate Dispersion masterbatch can improve the fluidity of plastics during processing, making products easier to form, and help improve production efficiency.

Carbonate chemistry-Improving appearance: Calcium Carbonate Dispersion can increase the whiteness, glossiness and surface smoothness of plastic products, and improve the appearance quality of products.

Carbonate chemistry-Environmental protection: In some disposable plastic products, the use of Calcium Carbonate Dispersion masterbatch helps to reduce the amount of resin, reduce the carbon footprint and resource consumption of plastic products, and play a certain role in promoting environmental protection.

Calcium Carbonate Dispersion masterbatch is mainly used in the production of plastic products such as films, injection molding, blow molding, pipes, and plates, and is widely used in packaging, home appliances, automobiles, building materials and other industries.

Calcium carbonate GENERIC® FUSE®

| Product name | D50 (μm) | D97 (μm) | Specific surface area (㎡/cm³) | Sieve residue 45μm (%) | Sieve residue 45μm (%) |

| V-N95 | 1.55~1.70 | 3.45~3.60 | 4.20~4.40 | <0.01 | 28~38 |

| V-N75 | 1.80~2.00 | 5.35~5.68 | 3.80~3.90 | <0.01 | 27~35 |

| V-N65 | 2.15~2.40 | 6.50~7.20 | 3.30~3.40 | <0.01 | 26~34 |

| V-N5 | 5.00~5.73 | 19.54~22.58 | 2.51~2.74 | <0.1 | 23~27 |

Packaging and shipping:

Package : 25kg PP bag/ Paper bag,.

500-1000kg/ton bag.

with pallet

Store in a dry and cool place. Stable storage for 5 years at room temperature.