- Victory

- China

- Quantity(Tons) 1 - 10 11 - 40 41 - 100 >100 Est. Time(days) 5 7 15 To be negotiated

- 2000T/Month

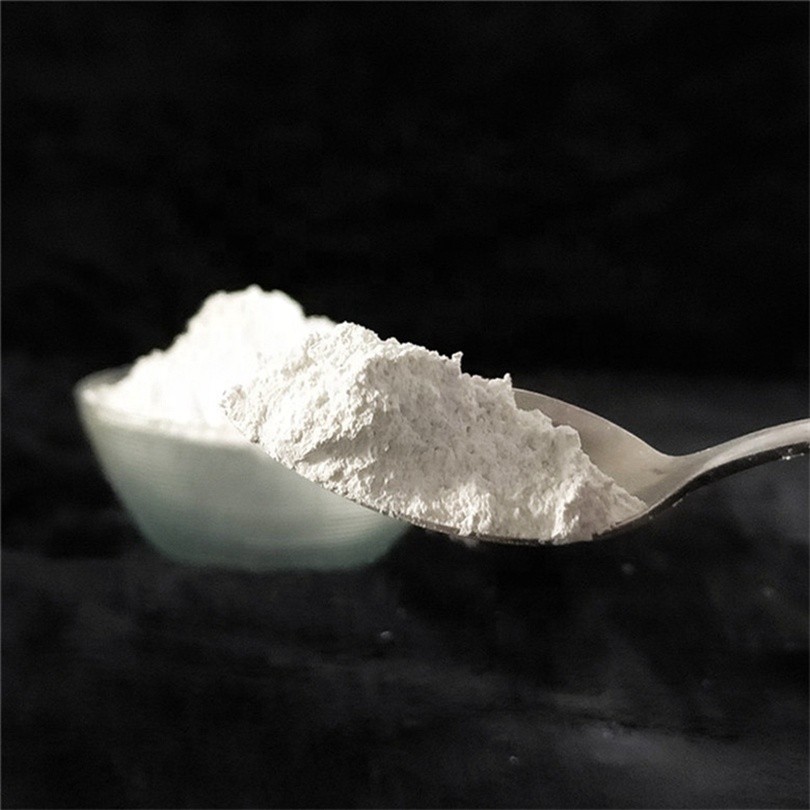

1.Calcium carbonate are excellent choices when utilized as additives during the production process.

2.Calcium carbonate is a mildly alkaline product and is used in a variety of environmental applications.

3.Calcium carbonate grades are granular and contain properties making them safe in pH adjustment, corrosion control and remineralization of reverse osmosis systems in water.

4.Calcium carbonate is utilized in vinyl flooring applications as a weighting and whiting agent, a cost-reducer or as a stiffener.

5.Calcium carbonate is used in a wide variety of rubber applications as both an extender and detacktifying agent. In other calcium carbonate rubber applications, it can add stiffness or provide abrasion resistance.

1. PP base materials are polypropylene based master batch containing75~85% super fine calcium carbonate (with strong polypropylene resin). It is natural white with excellent disparity

2. It can be mixed with Poly propylene resin for extrusion, thermal forming, injection etc. and is easy to disperse with good compatibility. It has function as a modifier to improve the heat resistance, flexural strength, size stability and printability. It also reduces heat release from burning and there force prevents further environmental pollution."

3. Calcium carbonate masterbatch is made of calcium carbonate, base resins and several plastic additives. Calcium carbonate (CaCO3) powder used in calcium carbonate masterbatch production has the natural origins. It exists in many forms such as calcite, limestone, chalk, marble or aragonite, or in the form of impurities and minerals such as dolomite. For thousands of years, CaCO3 has been one of the most useful minerals for humans, in different fields. And so far, one of the industries that use CaCO3 the most is probably the filler masterbatch industry.

4. Calcium Carbonate Masterbatch is a special filler developed with the customers consideration of achieving more and more transparency in the product. Very fine and high brightness of Talc ensures a very very smooth finish in the product along with very high shining.

Calcium carbonate GENERIC® FUSE®

Product name | D50 (μm) | D97 (μm) | Specific surface area (㎡/cm³) | Sieve residue 45μm (%) | Oil absorption (gr/100gr) |

V-N95 | 1.55~1.70 | 3.45~3.60 | 4.20~4.40 | <0.01 | 28~38 |

V-N75 | 1.80~2.00 | 5.35~5.68 | 3.80~3.90 | <0.01 | 27~35 |

V-N65 | 2.15~2.40 | 6.50~7.20 | 3.30~3.40 | <0.01 | 26~34 |

V-N5 | 5.00~5.73 | 19.54~22.58 | 2.51~2.74 | <0.1 | 23~27 |

Company Introduction:

LIAONING VICTORY FIRE-RETARDANT MATERIAL TECHNOLOGY CO.,LTD. is a research and development, production and sales of integrated company mainly operate inorganic fire retardant and non-metallic mineral products.

Our main productus contain Talc products, environmental flame retardants, such as Magnesium Hydroxide, Aluminium Hydroxide, Silica Flame Retardant and Composit Flame Retardant, CCM(MgO), Composit Magnesium Fertilizer,Kaolin,Chlorite,CaCO3,Barite,Perlite,Fluorite,Titanium Dioxide and other non-metallic materials.

Retardant.CCM(Mgo) ,Composit Magnesium Fertilizer,Kaolin,Cholite,Caco3,Barite,Perlite, Fluorite,Composit TiO2 .

Business philosophy: quality-oriented, honesty

Corporate culture: sincerely believe, seek change and win, and people are better

Corporate Vision: Unleash the Unlimited Potential of Inorganic Mineral Powders

Now the company passed ISO9001 quality system certification.

Our products comply with SGS, REACH, RoHS standard.

Our company produces and sells all kinds of products in strict accordance with the international standard. With rich experience and advanced research and development production technology, we not only assure products' quality but also improve the environmental benefits of products, to win the trustiness and support by the client from all over the world.

Packaging and shipping:

Package : 25kg PP bag/ Paper bag,.

500-1000kg/ton bag.

with pallet

Store in a dry and cool place. Stable storage for 5 years at room temperature.

Multiple transportation methods could be selected by customers, including Shipping, Air Transport, Rail Transport and Courier Transport.

We can offer higher cost performance in cargo transportation .

With more ten years experience in fine machining of non-metallic minerals , We provide comprehensive customer service from the initial consultation to the final delivery of your order.

We always serves with enthusiasm and accepts full responsibility in customers' work. Our priority is your satisfaction and growing solid relationships with each of our customers.

As we are extending our buisness all over the word,we are looking forward to cooperating with you in the future.

Our guarantee as below:

1) Goods quality will be same as samples, COA which supplied to you firstly.

2) Package also could be done accordingly to customer's request, safe and good look. Conform to standard of dangerous goods shipment. And photos will be taken during the process of container load, which will be supplied to each customers.

3) Shipment will be done by us, booking the direct, non-transfer vessel for prompt shipment. And shipping details will be advised.

4) After vessel left, the full set shipping documents will be scanned & delivered to you on time.

5) Any issues after picking up goods or during the usage, please contact us without hesitation.