- Victory

- China

- Quantity(Tons) 1 - 10 11 - 40 41 - 100 >100 Est. Time(days) 5 7 15 To be negotiated

- 2000T/Month

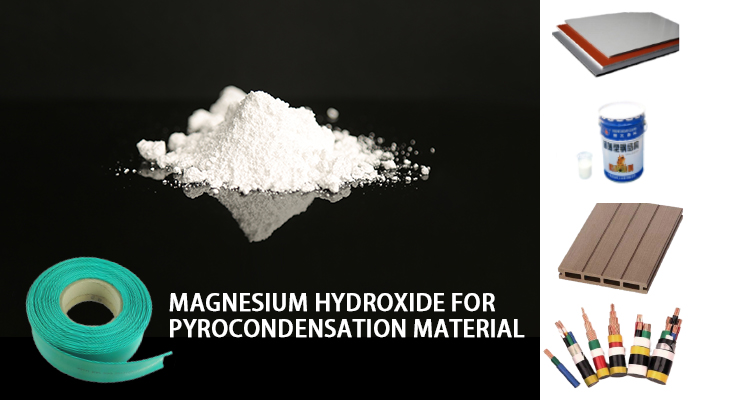

1.Magnesium hydrate is more cost effective than aluminum trihydrate (ATH).

2.Magnesium Hydroxide For Plastic has higher decomposition temperature and greater heat and smoke absorption capacity.

3.magnesium hydroxide for Thermal interface material is Halogen-free.

4.magnesium hydroxide for Thermal interface material has the advantages of melting drop resistance, carbonization promotion, non-volatilization, non-seepage, and no secondary pollution to the environment.

5.magnesium hydroxide for Thermal interface material is especially suitable for use with halogen-free flame retardant thermoplastic compounds, since incorporating the additive improves not only the flame retardant properties but also the dropping behavior and crust formation.

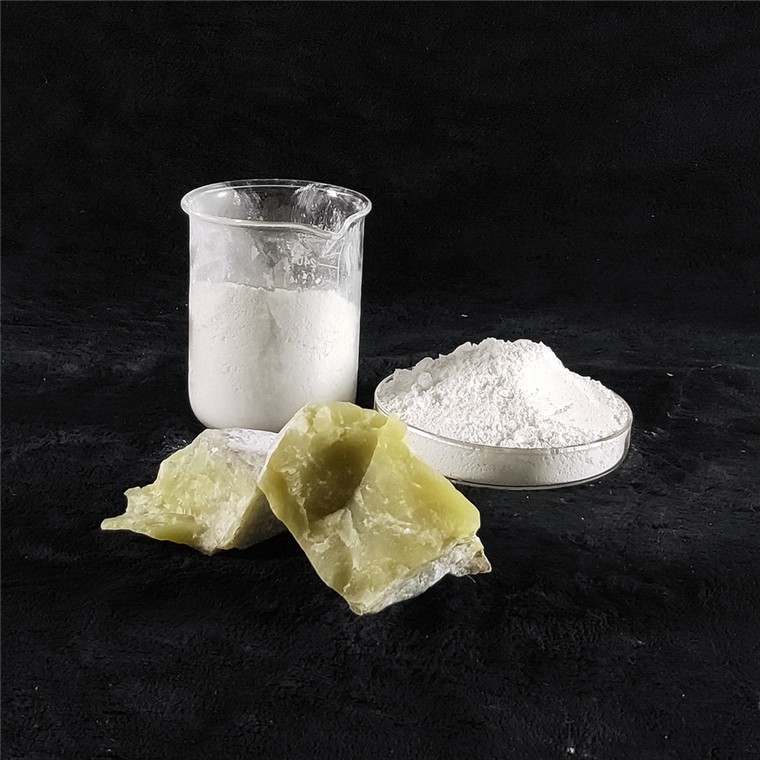

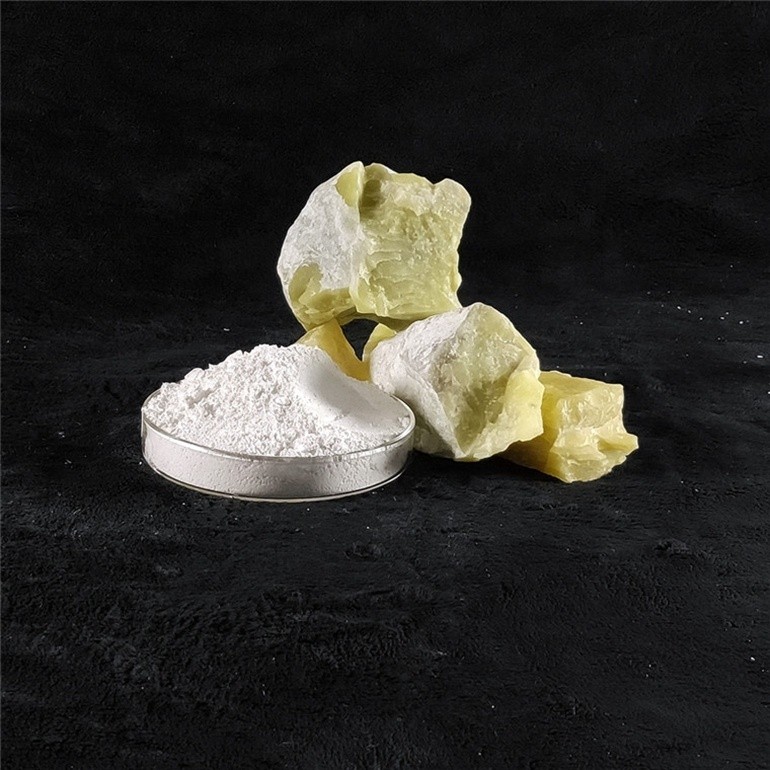

Magnesium hydrate (Mg(OH)₂), as an additive in plastics, is mainly used as a flame retardant and smoke suppressant. Compared with other flame retardants, Industrial Magnesium Oxide has the following advantages:

Magnesium hydrate has Good environmental protection: Magnesium Hydroxide For Plastic is a non-toxic, non-polluting and environmentally friendly flame retardant. It does not contain halogens and will not produce toxic halide gases when burned, so it is less harmful to the environment and human health.

Magnesium hydrate has High thermal stability: The decomposition temperature of Magnesium Hydroxide For Plastic is about 330°C, which is higher than that of aluminum hydroxide (Al(OH)₃), another common inorganic flame retardant (the decomposition temperature of aluminum hydroxide is 200- 220°C), suitable for higher temperature processing, which makes it particularly suitable for use in plastic materials molded at high temperatures.

Magnesium hydrate has Good flame retardant effect: During the combustion process, Magnesium Hydroxide For Plastic decomposes and releases water vapor by absorbing heat, and at the same time forms a protective layer of magnesium oxide, which helps to isolate the air and inhibit the spread of flames, thus improving the fire resistance of the material.

Magnesium hydrate has Suppress smoke generation: plastic grade Magnesium Hydroxide can not only effectively suppress flames, but also significantly reduce the amount of smoke generated during the combustion process.plastic grade Magnesium Hydroxide can improving the safety of materials in fires.

Magnesium hydrate has Synergy: plastic grade Magnesium Hydroxide can be used in conjunction with other flame retardants (such as phosphorus flame retardants) to enhance the flame retardant effect of the material.

Magnesium hydrate has Lower corrosiveness: Compared with some halogen-containing flame retardants, plastic grade Magnesium Hydroxide does not release corrosive gases when burned at high temperatures, causing less damage to equipment and the environment.

In summary, Industrial Magnesium Oxide, as a flame retardant in plastics, not only has good flame retardant effects and thermal stability, but also has the advantages of environmental protection and safety. Industrial Magnesium Oxide is suitable for use in plastic products that have high requirements for flame retardant properties.

Magnesium Hydroxide GENERIC® FUSE®

| Test Item | ||||||

| Product | Whiteness(%) Hunter method | Production Equipment | Particle size D50(μm) Laser diffraction | MgO(%) | Moisture(%) | Coated |

| V-1V | 91±1 | Vertical Mill | 4.5±0.5 | 58±1 | ≤0.5 | Yes |

| VC-2V | 91±1 | Vertical Mill | 5±5 | 59±1 | ≤0.5 | Yes |

| Test Item | ||||||

| Product | Whiteness(%) Hunter method | Production Equipment | Pass Rate(%) through 325 Mesh | MgO(%) | Moisture(%) | Coated |

| V3 | 88±1 | Raymond Mill | ≥98 | 53±1 | ≤0.5 | NO |

| V5 | 87±1 | Raymond Mill | ≥99 | 55±1 | ≤0.3 | NO |

| V8 | 86±1 | Raymond Mill | ≥98 | 58±1 | ≤0.5 | NO |

| V9 | 91±1 | Raymond Mill | ≥98 | 61±1 | ≤0.25 | NO |

Our guarantee as below:

1) Goods quality will be same as samples, COA which supplied to you firstly.

2) Package also could be done accordingly to customer's request, safe and good look. Conform to standard of dangerous goods shipment. And photos will be taken during the process of container load, which will be supplied to each customers.

3) Shipment will be done by us, booking the direct, non-transfer vessel for prompt shipment. And shipping details will be advised.

4) After vessel left, the full set shipping documents will be scanned & delivered to you on time.

5) Any issues after picking up goods or during the usage, please contact us without hesitation.