- Victory

- China

- Quantity(Tons) 1 - 10 11 - 40 41 - 100 >100 Est. Time(days) 5 7 15 To be negotiated

- 2000T/Month

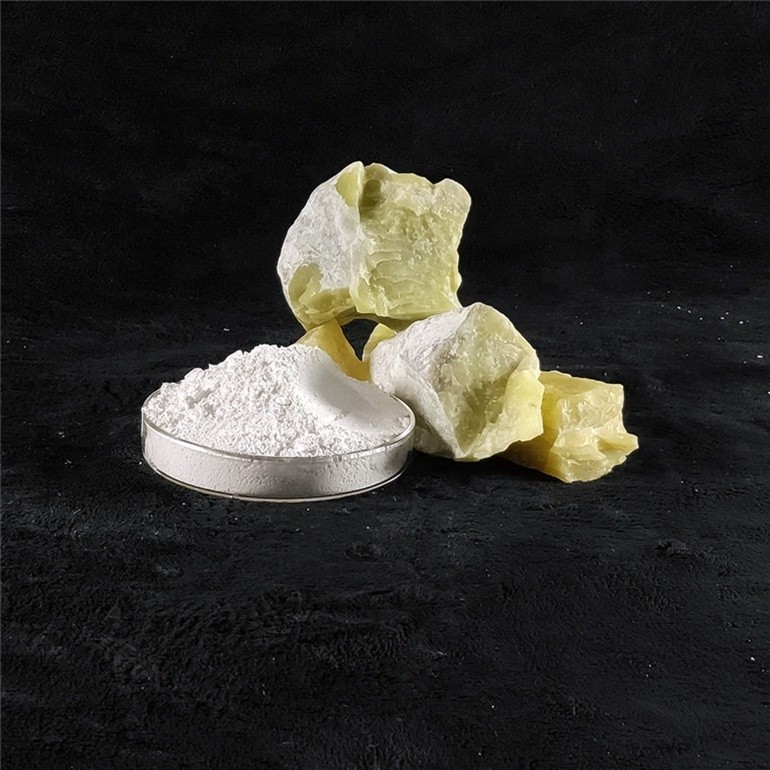

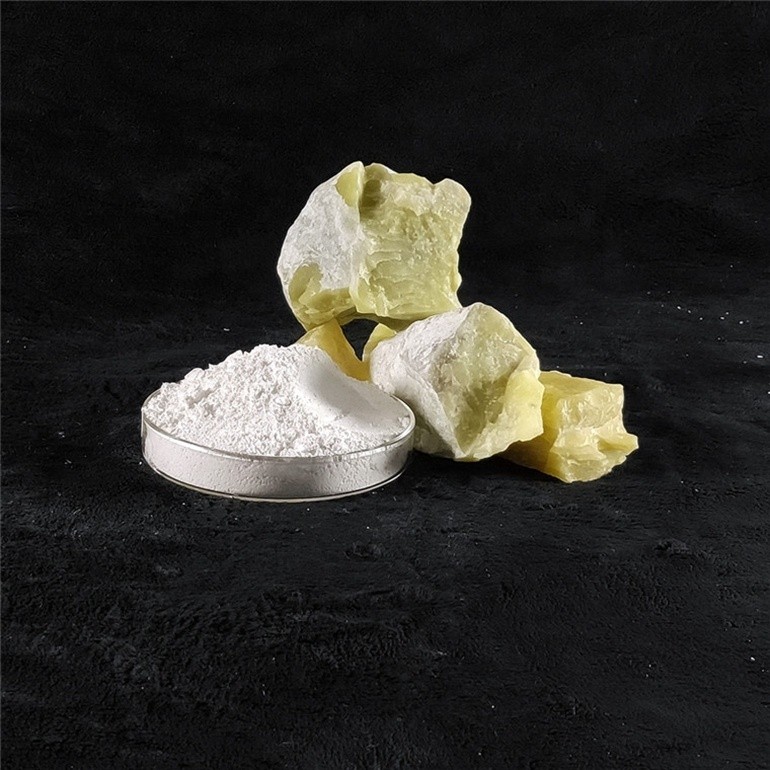

1.Mag hydroxide for Industrial CCL can improve the surface and mechanical properties of copper clad laminate.

2.Mag hydroxide for Industrial CCL (brucite) can be used as an environmentally friendly flame retardant in many industries.

3.Mag hydroxide for Industrial CCL can absorb the heat on the surface of the burning material and produce water.

4.Mag hydroxide for Industrial CCL is widely used in of smoke reduction and control.

1.Mag hydroxide For CCL has Excellent corrosion resistance and chemical stability:

Magnesium Hydroxide food grade shows good acid and alkali resistance and corrosion resistance in application, can exist stably in some chemical environments.Magnesium Hydroxide food grade is not prone to chemical reactions, which makes it an ideal choice for materials in some special fields.

2.Mag hydroxide For CCL has Low cost and high efficiency:

Compared with some high-performance organic flame retardants, Magnesium Hydroxide food grade is more economical. In practical applications, Magnesium Hydroxide food grade can achieve good flame retardant effects with lower filling amounts, and has high cost-effectiveness.

3.Mag hydroxide For CCL has Enhanced physical properties:

In addition to flame retardancy, Magnesium Hydroxides for Halogen Free Flame Retardants is also a good filler that can enhance the mechanical strength, wear resistance and dimensional stability of materials. Especially in plastic products, the use of Magnesium Hydroxides for Halogen Free Flame Retardants can improve the physical properties of materials such as rigidity and hardness.

4.Mag hydroxide For CCL has Synergistic effect with other flame retardants:

Magnesium Hydroxides for Halogen Free Flame Retardants can synergize with other flame retardants (such as aluminum hydroxide, phosphorus flame retardants, etc.) to further improve the flame retardant properties of materials and optimize the flame retardant effect according to application requirements.

Magnesium Hydroxide GENERIC® FUSE®

| Test Item | ||||||

| Product | Whiteness(%) Hunter method | Production Equipment | Particle size D50(μm) Laser diffraction | MgO(%) | Moisture(%) | Coated |

| V-1V | 91±1 | Vertical Mill | 4.5±0.5 | 58±1 | ≤0.5 | Yes |

| VC-2V | 91±1 | Vertical Mill | 5±5 | 59±1 | ≤0.5 | Yes |

| Test Item | ||||||

| Product | Whiteness(%) Hunter method | Production Equipment | Pass Rate(%) through 325 Mesh | MgO(%) | Moisture(%) | Coated |

| V3 | 88±1 | Raymond Mill | ≥98 | 53±1 | ≤0.5 | NO |

| V5 | 87±1 | Raymond Mill | ≥99 | 55±1 | ≤0.3 | NO |

| V8 | 86±1 | Raymond Mill | ≥98 | 58±1 | ≤0.5 | NO |

| V9 | 91±1 | Raymond Mill | ≥98 | 61±1 | ≤0.25 | NO |

Company Introduction:

Corporate Philosophy: Quality is fundamental, integrity is the foundation.

Corporate Mission: To build a one-stop shopping platform for high-quality functional non-metal products.

Corporate Vision: To be among the top, with a global perspective, and to unleash the infinite potential of non-metal resources.

Core Corporate Values: Customer first, teamwork, unity of knowledge and action, deep contemplation, continuous improvement, and dedication to one's profession.