- Victory

- China

- Quantity(Tons) 1 - 10 11 - 40 41 - 100 >100 Est. Time(days) 5 7 15 To be negotiated

- 2000T/Month

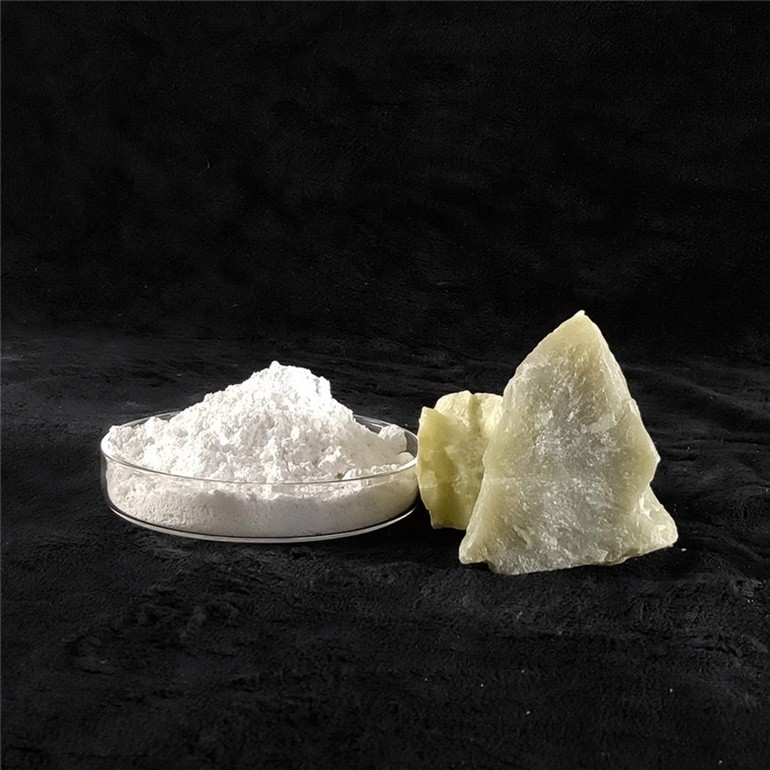

1.Mag hydroxide for dyes has unique buffering and neutralization capability.

2.Mag hydroxide for dyes has higher decomposition temperature and greater heat absorption.

3.Mag hydroxide for dyes is a very finely grounded product having an extremely uniform and narrow particle size distribution as well. And is considered as an non halogenated, environment friendly and non toxic mineral based flame retardant & smoke suppressant for various plastics & rubber applications.

4.The effectiveness of flame – retardant and smoke suppressant is better than Aluminum Hydroxide.

5.Mag hydroxide for dyes has strong reinforcement due to high fineness & the surface is coated specially.

Magnesium hydroxide for dyes has many advantages, especially in terms of environmental protection and performance, and is often used as a filler or auxiliary material in the dye production process. The following are Magnesium hydroxide for dyes main advantages:

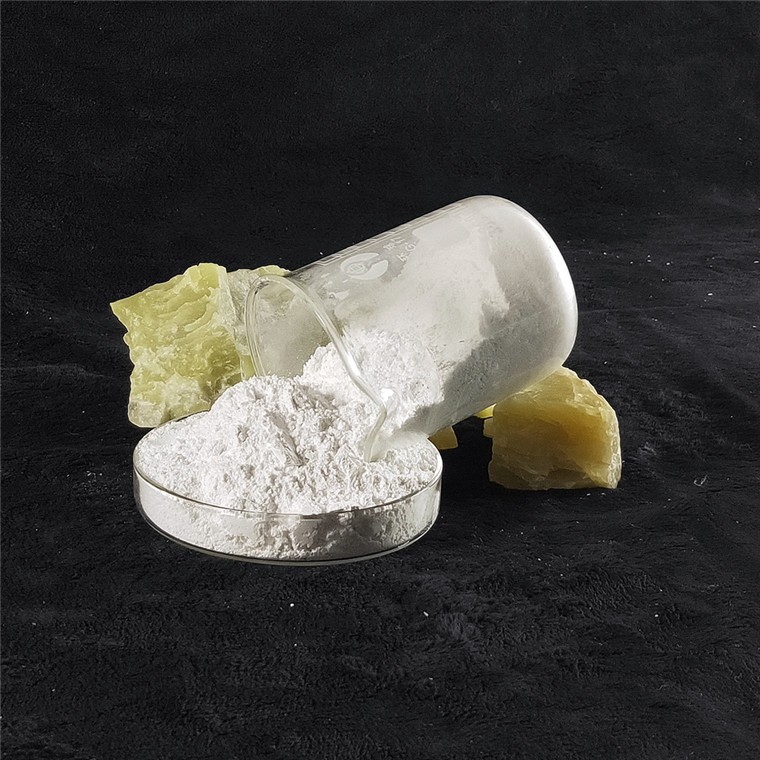

Environmental characteristics:

Magnesium hydroxide for dyes is a non-toxic and harmless substance, a green and environmentally friendly material.Mag hydroxide For Dyeing Sewage will not cause secondary pollution to the environment,Mag hydroxide For Dyeing Sewage meets the current requirements of the dye industry for environmental protection and sustainable development.

After decomposition, it produces water and magnesium oxide, and will not release harmful gases or heavy metals, which is more environmentally friendly.

Flame retardancy:

Optimization and modelling of Mag hydroxide For Dyeing Sewage has good flame retardant properties. During the dye processing process, it can decompose and absorb heat, release water vapor, thereby reducing the temperature and reducing the risk of combustion.

Filling and reinforcing effect:

Optimization and modelling of magnesium oxide can be used as a filler in the dye system, which can increase the volume of the dye and improve its mechanical properties, such as hardness and wear resistance, without significantly affecting the color quality of the dye.

PH adjustment:

In some dye production processes, Optimization and modelling of magnesium oxide can play a certain pH buffering role, Optimization and modelling of magnesium oxide helps to maintain the pH stability in the process and avoid excessive acid-base reactions of dyes during production or storage.

Cost-effectiveness:

Compared with other inorganic fillers such as alumina, Mag hydroxide For Dyeing Sewage is relatively cheap and economical to use, which can effectively reduce production costs.

Adsorption capacity:

In the production of some dyes, Mag hydroxide for dyes can adsorb some harmful by-products or impurities, improving the purity and quality of the dyes.

In general, Magnesium hydroxide for dyes, as an additive in dye production, can improve product performance and reduce costs. It also has good environmental protection characteristics, which is in line with the development trend of the modern dye industry.

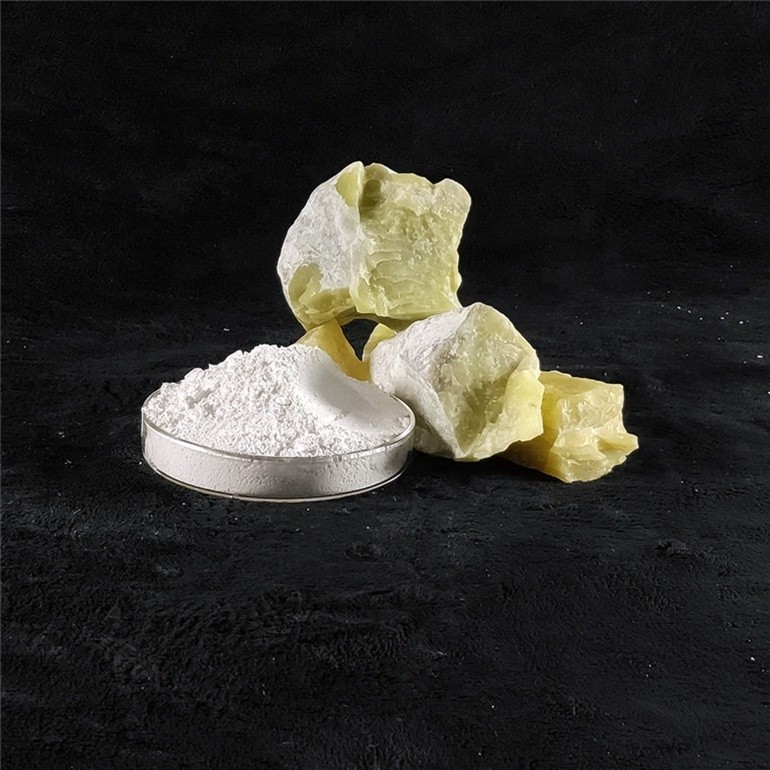

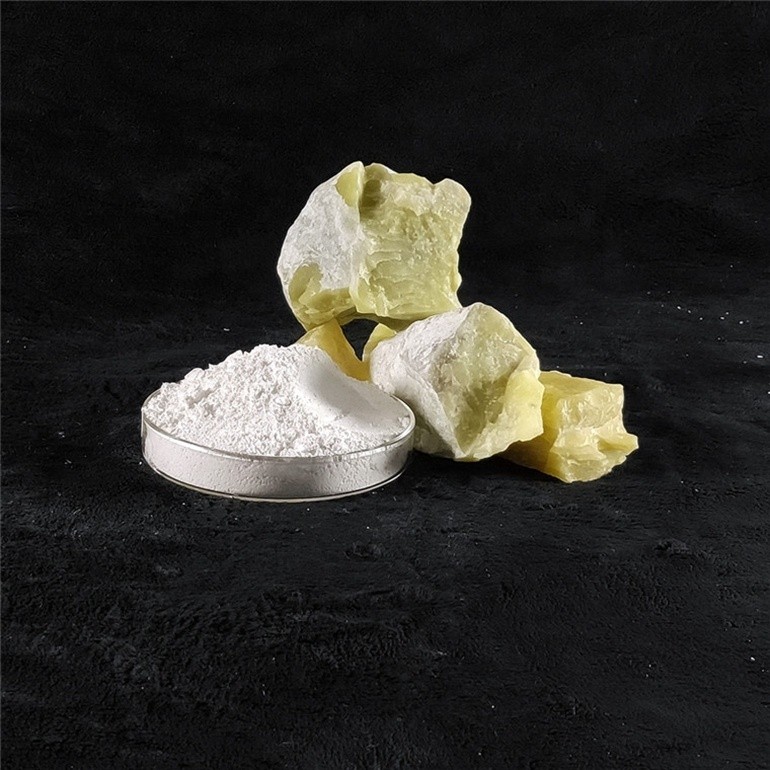

Magnesium Hydroxide GENERIC® FUSE®

| Test Item | ||||||

| Product | Whiteness(%) Hunter method | Production Equipment | Particle size D50(μm) Laser diffraction | MgO(%) | Moisture(%) | Coated |

| V-1V | 91±1 | Vertical Mill | 4.5±0.5 | 58±1 | ≤0.5 | Yes |

| VC-2V | 91±1 | Vertical Mill | 4.5±0.5 | 59±1 | ≤0.5 | Yes |

| Test Item | ||||||

| Product | Whiteness(%) Hunter method | Production Equipment | Pass Rate(%) through 325 Mesh | MgO(%) | Moisture(%) | Coated |

| V3 | 88±1 | Raymond Mill | ≥98 | 53±1 | ≤0.5 | NO |

| V5 | 87±1 | Raymond Mill | ≥99 | 55±1 | ≤0.3 | NO |

| V8 | 86±1 | Raymond Mill | ≥98 | 58±1 | ≤0.5 | NO |

| V9 | 91±1 | Raymond Mill | ≥98 | 61±1 | ≤0.25 | NO |

Company Introduction:

Founded in 2019, the comapmy is a global supplier of halogen-free flame retardant material and Nonmetallic ultrafine nano-powder.

We are a comprehensive company intergrating R&D, productoion and sales, have more than 200 employees and opreate oversea, producing in own mines, serving more than hundred customers including the world’s top 500 enterprises in Europe, Japan, South Korea and Sourheast Asia.

we are committed to providing for domestic and foreign customers with high quality and high technology products and services in related application industries.