Preparation method and application of high purity magnesium oxide powder and magnesium oxide ceramics

The high purity magnesium oxide powder material is an important high temperature resistant material and the magnesium oxide ceramics prepared by it are widely used in the field of transparent materials. Transparent magnesia ceramic is a kind of optical isotropic material, which has the advantages of good alkali resistance, high melting point, high thermal conductivity, small theoretical density, high insulation and high infrared transmittance. High quality refractory transparent magnesia ceramics is a promising material, its performance is better than alumina ceramics, has a wide range of applications in the field of visible light and infrared transparent materials.

1. Preparation method of high purity MgO powder

High purity magnesium oxide powder refers to sintered magnesium oxide with MgO mass fraction greater than 99% (MgO mass fraction greater than 98% in China) and volume density greater than 3.40g/cm3. The preparation of high purity MgO is made of magnesium-containing compounds as raw materials, some of which are light burned magnesium oxide and then electromelted or refired to get high purity magnesium oxide, and some of which are directly calcined or pyrolyzed to get high purity magnesium oxide. At present, the main preparation methods include direct calcination, brine precipitation, brine direct pyrolysis and electromelting.

Morphology and control process of different high purity magnesium oxide powder

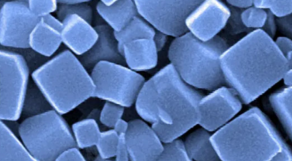

1. Cubic massive magnesium oxide powder

Cubic block high purity magnesium oxide powder is prepared by electromelting method, particle size distribution is uniform, can be used to prepare transparent magnesium oxide ceramics and electronic materials filler. In addition, the electromelting method can also be used to prepare single crystalline MgO with purity of more than 99.9%. It is widely used as the substrate of new materials, such as high temperature superconducting film, ferroelectric film of MRAM, etc.

3. Flake magnesium oxide powder

The preparation of rhombohedral flake magnesia powder is based on low-grade dolomite as raw material, brine precipitation method, secondary acid leaching, ammonia precipitation method to prepare the precursor magnesium hydroxide, calcination to get rhombohedral lamellar multi-pore structure of nano MgO crystal, the magnesium oxide is a good crystal, cubic crystal system, thickness of about 10 ~ 20nm. The daisy-like two-dimensional rhombohedral lamellar void structure with a maximum area of 1μm2 is widely used in advanced ceramic materials, cosmetics, paints, rubber fillers, catalyst carriers and other fields. It also has important application prospects and great economic potential in military, quantum devices, microelectronics and other fields.