- Victory

- China

- Quantity(Tons) 1 - 10 11 - 40 41 - 100 >100 Est. Time(days) 5 7 15 To be negotiated

- 2000T/Month

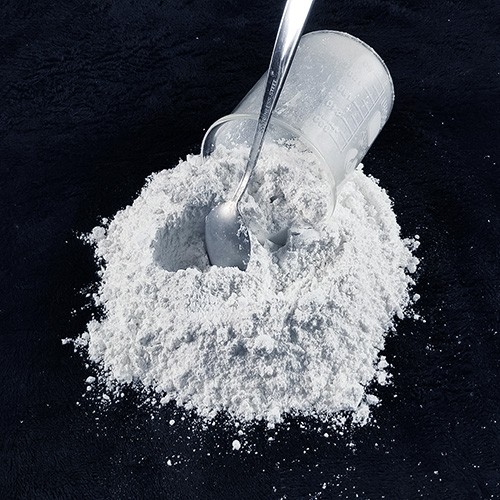

1.Exterior Wall Coating Grade Talc has high specific surface, talc works also as dusting/partitioning agent for sticky compounds, improving handling and preventing agglomeration.

2.Exterior Wall Coating Grade Talc has low abrasion resistance.

3.Exterior Wall Coating Grade Talc has good rheological property,due to its high oil absorption.

4.Talc in Paint Industry has a low friction factor, which can make the coating surface smooth and pliable.

5.Talc in Paint Industry has a low friction factor, which can reduce the fracture of the coating and reduce the printing pressure.

Using Talcum powder as filler in paint imparts valuable properties to the final product

1.Talc in Paint Industry can Improved coverage properties:

Talcum powder increases the pseudoplasticity of the paint. Pseudoplasticity refers to the reduction of viscosity when shear forces are applied. Thus, Talcum powder is less strenuous to apply and the desired thickness of the paint film can be achieved.

2.Talc in Paint Industry can Improved durability of the applied paint:

Talcum powder is chemically inert and does not react with air, acid, water etc.

Talcum powder is an excellent carrier for anti-corrosive primers.

Individual layers of Talcum powder are strong. Therefore, its presence strengthens the paint film.

Talcum powder is hydrophobic in nature and therefore offers the paint film resistance to wet scrubbing.

3.Talc in Paint Industry can Improved visual properties:

Talc For Exterior Wall Coating has high whiteness and therefore interferes minimally with the shade of the pigment.

Talc For Exterior Wall Coating has high brightness due to which the paint doesn’t dull in appearance.

4.Improved adhesion properties:

Moreover, we can manufacture various grades of Talc For Exterior Wall Coating depending on the application in the paint industry.

The platy shape of Talc for coating minimizes the shrinkage of binder system during curing of the paint film and thus promotes the adhesion of paint film to the surface. Color, particle size, oil absorption and acid solubility are the main criteria for selecting Talc for coating manufacture.

General Purpose Talc FUSE®

| Product | Test Item | ||||||

| Whiteness (%) | Particle size D50 (μm) | 45μm residue (%) | Moisture content (%) | Moisture content (%) | Specific surface area (㎡/g) | Oil absorption (ml/100g) | |

| F80-12 | 80 | 12 | 0.3 | 0.3 | 0.4 | 4.5 | 28 |

| F83-8 | 83 | 8 | 0.1 | 0.3 | 0.3 | 10 | 35 |

| F85 | 83 | 8 | 0.1 | 0.3 | 0.3 | 10 | 35 |

| F90-7 | 88 | 17 | 0.2 | 0.2 | 0.4 | 3.5 | 24 |

| F90-3 | 91 | 14 | 0.2 | 0.2 | 0.3 | 5 | 26 |

| F92-5 | 93 | 15 | 0.2 | 0.2 | 0.4 | 4 | 25 |

| F94-3 | 94 | 14 | 0.2 | 0.3 | 0.35 | 4 | 26 |

| F94-7 | 94 | 18 | 0.5 | 0.2 | 0.35 | 5.5 | 23 |

Company Introduction:

LIAONING VICTORY FIRE-RETARDNT MATERIAL TECHNOLOGY CO., LTD. is a research and development, production and sales of integrated company mainly operate inorganic fire retardant and non-metallic mineral products.

Our main productus contain Talc product, environmental flame retardant, such as Magnesium Hydroxide,Aluminium Hydroxide, Silica Flame Retardant and Composit Flame.