- Victory

- China

- Quantity(Tons) 1 - 10 11 - 40 41 - 100 >100 Est. Time(days) 5 7 15 To be negotiated

- 2000T/Month

1.Talc can improve the rigidity of products, reduce shrinkage rate.

2.Talc powder has good suspension and dispersability.

3.Talc powder has a low friction factor, which can reduce the fracture of the coating and reduce the printing pressure.

4. The gloss talc, stable chemical performance, strong hiding power, can prevent the paint coating aging rupture and improve the ability of resistance to weathering.

5.Talc an improve the toughness of the productes.

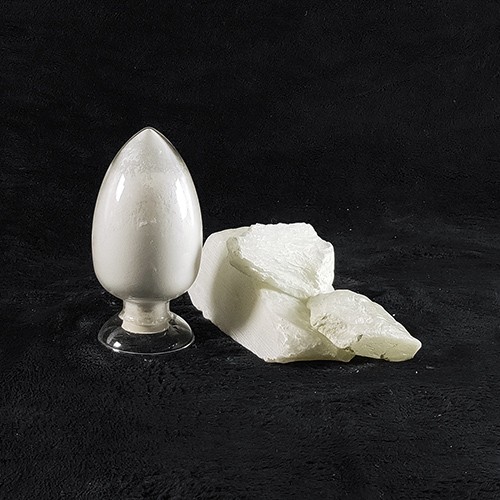

Using talc as filler in paint imparts valuable properties to the final product

1.Improved coverage properties:

It is less strenuous to apply and the desired thickness of the paint film can be achieved.

2.Improved durability of the applied paint:

Talc’s particle form is platy, which is important for optimum filler packing in the paint film. The platy particles also create a good barrier against unwanted substances such as water, CO2 and O2.

Talc is an excellent carrier for anti-corrosive primers.

Individual layers of talc are strong. Therefore, its presence strengthens the paint film.

3.Improved visual properties:

Talc has high whiteness and therefore interferes minimally with the shade of the pigment.

Talc has high brightness due to which the paint doesn’t dull in appearance.

Talc lessens the requirement of solvent for the pigment, thereby causing minimum dilution of pigment as well as improving cost.

4.Improved adhesion properties:

We have talc of high whiteness, low oil absorption, low acid solubility and fine particle size so to impart the right quality to the paint.

Moreover, we can manufacture various grades of talc depending on the application in the paint industry.

Our talc can be used in architectural paints, industrial paints, extenders to name a few.

General Purpose Talc FUSE®

General-purpose talc is used for blended fillers in a wide range of fields, including the plastic, paper, rubber, paints, and ceramic application fields.。

| Test Item | |||||||

| Product | Whiteness (%) | Particle size D50 (μm) | 45μm residue (%) | Moisture content (%) | Apparent density (g/ml) | Specific surface area (㎡/g) | Oil absorption (ml/100g) |

| F80-12 | 80 | 12 | 0.3 | 0.3 | 0.4 | 4.5 | 28 |

| F83-8 | 83 | 8 | 0.1 | 0.3 | 0.3 | 10 | 35 |

| F85 | 83 | 8 | 0.1 | 0.3 | 0.3 | 10 | 35 |

| F90-7 | 88 | 17 | 0.2 | 0.2 | 0.4 | 3.5 | 24 |

| F90-3 | 91 | 14 | 0.2 | 0.2 | 0.3 | 5 | 26 |

| F92-5 | 93 | 15 | 0.2 | 0.2 | 0.4 | 4 | 25 |

| F94-3 | 94 | 14 | 0.2 | 0.3 | 0.35 | 4 | 26 |

| F94-7 | 94 | 18 | 0.5 | 0.2 | 0.35 | 5.5 | 23 |