- Victory

- China

- Quantity(Tons) 1 - 10 11 - 40 41 - 100 >100 Est. Time(days) 5 7 15 To be negotiated

1.Talc for peroxide cured compounds has a low friction factor.

2.Talc for peroxide cured compounds can reduce the fracture of the coating.

3.Talc for peroxide cured compounds has high specific surface, Matrix polymer for talc works also as dusting/partitioning agent for sticky compounds, improving handling and preventing agglomeration.

4.Matrix polymer for talc has platy structure and organophilicity, talc represents a good modifier for elastomers enhancing rigidity and barrier properties.

5.Matrix polymer for talc can improve the mechanical properties of the products.

Application of talc powder in coatings in coatings is mainly reflected in the following aspects:

1.Filler: As an inorganic filler, Matrix polymer for talc can increase the volume and thickness of the coating, reduce costs, and improve the rheology and coating properties of the coating.

2.Thickener: Application of talc powder in coatings can enhance the viscosity of the coating, improve the suspension of the coating, and prevent precipitation.

Application of Talc in Plastic Modification has the following detailed advantages:

1.Improve rigidity and dimensional stability: Application of Talc in Plastic Modification can significantly improve the rigidity and dimensional stability of plastics and prevent the creep of molded parts at high temperatures.

2.Improve high-temperature creep resistance: Application of Talc in Plastic Modificationcan effectively improve the high-temperature creep resistance of plastics and increase the number of molding turnovers.

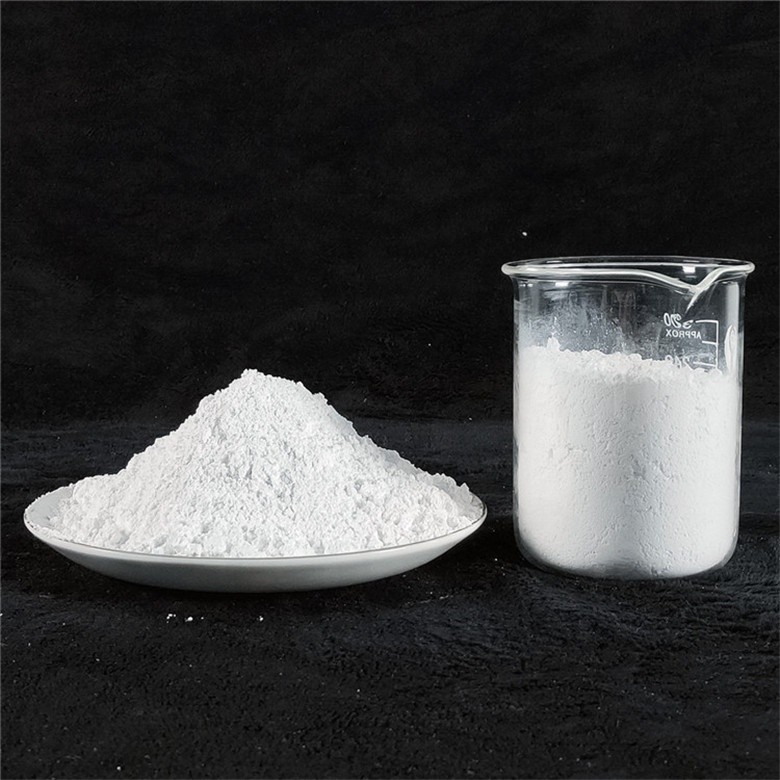

General Purpose Talc FUSE®

General-purpose talc is used for blended fillers in a wide range of fields, including the plastic, paper, rubber, paints, and ceramic application fields.。

| Product | Test Item | ||||||

| Whiteness (%) | Particle size D50 (μm) | 45μm residue (%) | Moisture content (%) | Apparent density (g/ml) | Specific surface area (㎡/g) | Oil absorption (ml/100g) | |

| F80-12 | 80 | 12 | 0.3 | 0.3 | 0.4 | 4.5 | 28 |

| F83-8 | 83 | 8 | 0.1 | 0.3 | 0.3 | 10 | 35 |

| F85 | 83 | 8 | 0.1 | 0.3 | 0.3 | 10 | 35 |

| F90-7 | 88 | 17 | 0.2 | 0.2 | 0.4 | 3.5 | 24 |

| F90-3 | 91 | 14 | 0.2 | 0.2 | 0.3 | 5 | 26 |

| F92-5 | 93 | 15 | 0.2 | 0.2 | 0.4 | 4 | 25 |

| F94-3 | 94 | 14 | 0.2 | 0.3 | 0.35 | 4 | 26 |

| F94-7 | 94 | 18 | 0.5 | 0.2 | 0.35 | 5.5 | 23 |

Company Introduction:

LIAONING VICTORY FIRE-RETARDANT MATERIAL TECHNOLOGY CO.,LTD. is a research and development, production and sales of integrated company mainly operate inorganic fire retardant and non-metallic mineral products.

Business philosophy: quality-oriented, honesty

Corporate culture: sincerely believe, seek change and win, and people are better

Corporate Vision: Unleash the Unlimited Potential of Inorganic Mineral Powders