- Victory

- China

- Quantity(Tons) 1 - 10 11 - 40 41 - 100 >100 Est. Time(days) 5 7 15 To be negotiated

- 2000T/Month

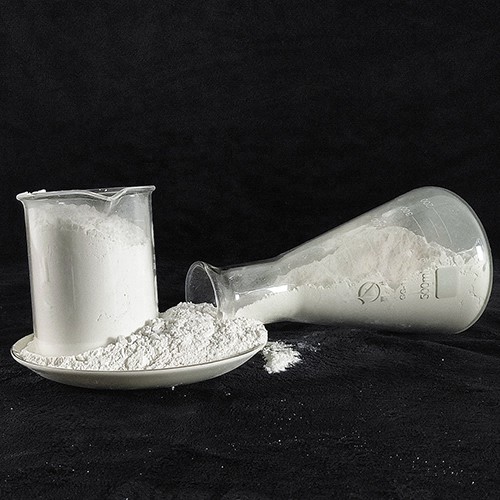

1.Talc Powder for Paints and Coating Industry can corrosion resistance.

2.Talc Powder for Paints and Coating Industry can improve dimensional stability, reduce thermal expansion, shrinkage, warping and other properties.

3.Talc Powder for Paints and Coating Industry can increases the hardness of paint film.

4.Talc Powder for Paint Industry has the advantage of high whiteness, uniform granularity and strong dispersibility.

5.Talc Powder for Paint Industry has high specific surface, talc works also as dusting/partitioning agent for sticky compounds, improving handling and preventing agglomeration.

The Application of Talcum Powder in Coatings is not limited to being used as a filler, but also has certain anti-corrosion functions. Fine Talc for Grounds, Paints, and Pastels advantages are as follows:

Application of Talcum Powder in Coatings is Enhance the waterproofness of the coating: Fine Talc for Grounds, Paints, and Pastels itself is hydrophobic.Talc Powder for Paint Industry can reduce the penetration and absorption of water, prevent water from entering the substrate under the coating, and thus reduce the risk of corrosion. This is very important for anti-corrosion coatings, especially when used in humid environments.

Application of Talcum Powder in Coatings is Improve the density of the coating: The fine particles of Fine Talc for Grounds, Paints, and Pastels can fill the tiny gaps in the coating, making the coating denser, blocking the penetration of air, water and chemicals, and further enhancing the anti-corrosion effect.

Application of Talcum Powder in Coatings is Chemical resistance: Fine Talc for Grounds, Paints, and Pastels has good chemical inertness and is not easy to react with acids, alkalis or other corrosive substances. talc for oil paint can improve the tolerance of coatings in corrosive environments. This chemical resistance is particularly critical for anti-corrosion coatings.

talc for oil paint can Improve the crack resistance of the coating: Since talc for oil paint can improve the flexibility and crack resistance of the coating, talc for oil paint helps prevent the coating from cracking due to external factors (such as temperature changes, mechanical stress), thereby avoiding the penetration of water or corrosive substances in the cracks and protecting the substrate from corrosion.

Talc Powder for Paint Industry can Improve durability: The addition of talc for oil paint can enhance the mechanical properties of the coating, especially the wear resistance and hardness, so that the coating can maintain integrity and stability during long-term use, thereby extending the anti-corrosion life of the paint.

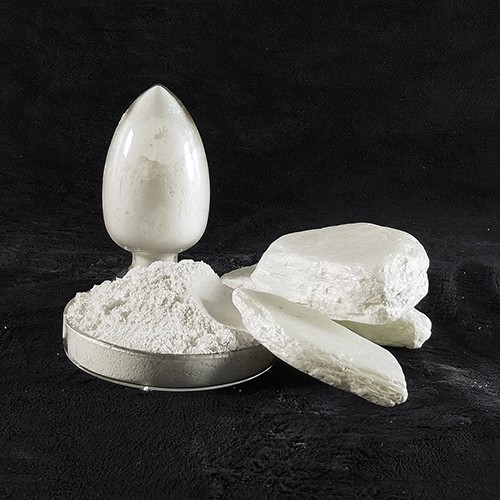

GENERIC® makes use of the inherent characteristics of talc, such as high whiteness, a plate-like crystal shape, and chemical resistance, and has a wide range of applications, including those for general-purpose resin, functional resin, electrical materials (e.g., resist ink and adhesive), and automotive paints.

| Test Item | ||||||

| Product | Whiteness (%) | Particle size D50 (μm) | Moisture content (%) | Apparent density (g/ml) | Specific surface area (㎡/g) | Oil absorption (ml/100g) |

| G-3C | 96 | 2.8 | 0.2 | 0.12 | 12 | 45 |

| G-2C | 96 | 4 | 0.2 | 0.13 | 10.5 | 44 |

| G-1C | 90 | 5 | 0.2 | 0.15 | 9 | 40 |

| GP-5 | 96 | 5 | 0.2 | 0.15 | 8 | 40 |

| GP-5 | 96 | 7 | 0.2 | 0.18 | 7.5 | 36 |

| G-1CB | 94 | 8 | 0.2 | 0.25 | 7 | 35 |

General Purpose Talc FUSE®

General-purpose talc is used for blended fillers in a wide range of fields, including the plastic, paper, rubber, paints, and ceramic application fields.。

| Test Item | |||||||

| Product | Whiteness (%) | Particle size D50 (μm) | 45μm residue (%) | Moisture content (%) | Apparent density (g/ml) | Specific surface area (㎡/g) | Oil absorption (ml/100g) |

| F80-12 | 80 | 12 | 0.3 | 0.3 | 0.4 | 4.5 | 28 |

| F83-8 | 83 | 8 | 0.1 | 0.3 | 0.3 | 10 | 35 |

| F85 | 83 | 8 | 0.1 | 0.3 | 0.3 | 10 | 35 |

| F90-7 | 88 | 17 | 0.2 | 0.2 | 0.4 | 3.5 | 24 |

| F90-3 | 91 | 14 | 0.2 | 0.2 | 0.3 | 5 | 26 |

| F92-5 | 93 | 15 | 0.2 | 0.2 | 0.4 | 4 | 25 |

| F92-5 | 94 | 14 | 0.2 | 0.3 | 0.35 | 4 | 26 |

| F94-7 | 94 | 18 | 0.5 | 0.2 | 0.35 | 5.5 | 23 |

Company Introduction:

Founded in 2019, the comapmy is a global supplier of halogen-free flame retardant material and Nonmetallic ultrafine nano-powder.

We are a comprehensive company intergrating R&D, productoion and sales, have more than 200 employees and opreate oversea, producing in own mines, serving more than hundred customers including the world’s top 500 enterprises in Europe, Japan, South Korea and Sourheast Asia.

we are committed to providing for domestic and foreign customers with high quality and high technology products and services in related application industries.We can provide samples, and the preparation time is about one week.