- Victory

- China

- Quantity(Tons) 1 - 10 11 - 40 41 - 100 >100 Est. Time(days) 5 7 15 To be negotiated

- 2000T/Month

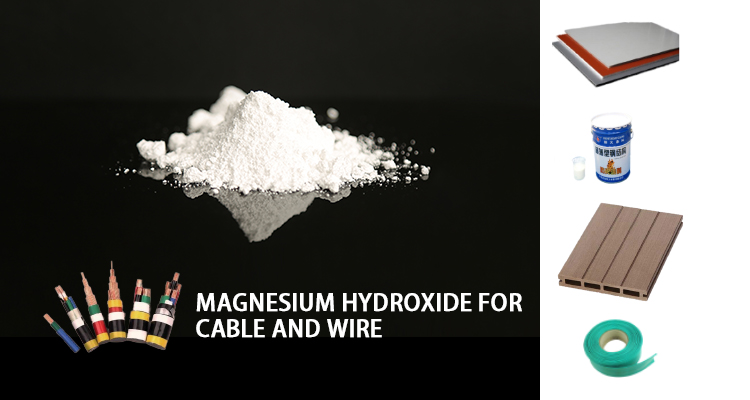

1.Magnesium Hydroxide for LSZH Flame Retardant has small influence mechanical property .

2.Magnesium Hydroxide for LSZH Flame Retardant Extrusion, molding under pressure non-toxic, safe to handle and store and meet all legal requirements of environmental protection.

3.Magnesium Hydroxide for LSZH Flame Retardant is More effective smoke suppressant than ATH.

4. Magnesium Hydroxide for LSZH Flame Retardant can be used alone or in combination with other flame retardants with excellent processing flow properties.

5.Magnesium Hydroxides for Halogen Free Flame Retardants has good performance in the formulation of PVC other wires.

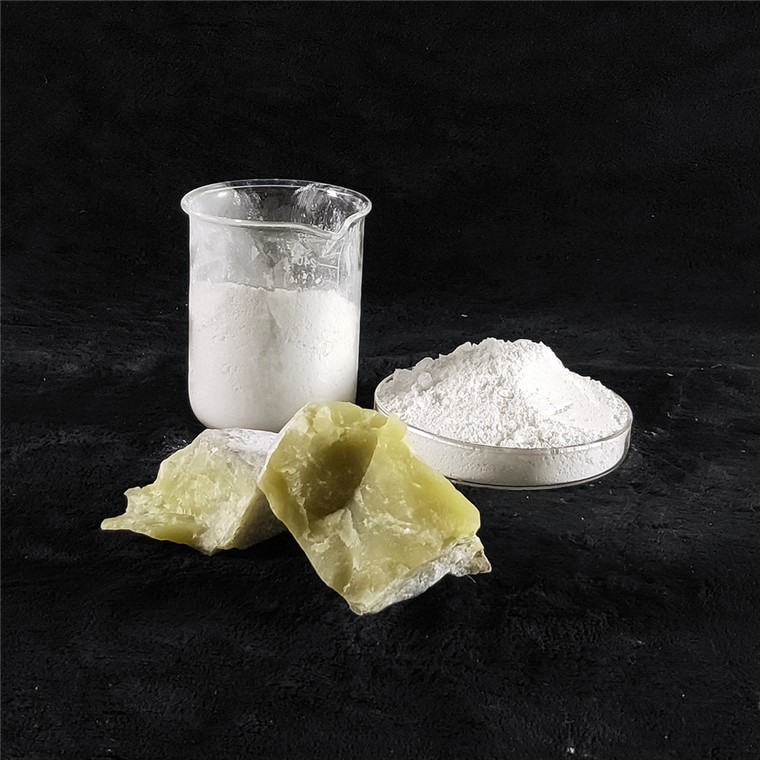

Magnesium Hydroxides for Halogen Free Flame Retardants is used practically for all types of plastics and filled copolymer compositions based on PVC, PA PS, PP, PE, PET, EVA IPM etc. Magnesium Hydroxides for Halogen Free Flame Retardants is a highly non-toxic, inorganic flame retardant, filler and smoke suppressive additive.

Magnesium Hydroxides for Fire resistant fiber optic cable with 90-99% basic substance content is used as vulcanization activator for rubber, filler and reinforcing material in rubber compounds.

In industrial rubber goods production Magnesium Hydroxides for Fire resistant fiber optic cable is added to crude rubber compound when vulcanized together with metal parts during vulcanization of chloroprene rubbers.Higher than 500 ℃ water lost into magnesium oxide.

Magnesium Hydroxides for Fire resistant fiber optic cable is a kind of inorganic weak base products, because of its good buffer performance, higher activity and adsorption capacity.

Magnesium Hydroxides for Fire resistant fiber optic cable is a very finely grounded product having an extremely uniform and narrow particle size distribution as well. And is considered as an non halogenated, environment friendly and non toxic mineral based flame retardant & smoke suppressant for various plastics & rubber applications.

Effect of surface modification of magnesium hydroxide can significantly improve its performance and enhance its compatibility and dispersibility with other materials.

In addition, Effect of surface modification of magnesium hydroxide also exhibits better performance in heat resistance, flame retardancy and UV resistance, and is suitable for applications such as high-performance cables and plastics.

Magnesium Hydroxide GENERIC® FUSE®

Product | Test Item | |||||

Whiteness(%) | Production Equipment | Particle size D50(μm) | MgO(%) | Moisture(%) | Coated | |

V-1V | 91±1 | Vertical Mill | 4.5±0.5 | 58±1 | ≤0.5 | Yes |

VC-2V | 91±1 | Vertical Mill | 5±5 | 5 59±1 | ≤0.5 | Yes |

Product | Test Item | ||||||

Whiteness(%) | Production Equipment | Particle size D50(μm) | D100(um) | MgO(%) | Moisture(%) | Coated | |

V-1J | 92±1 | JET | 3.0±0.2 | 30±2 | 59±1 | ≤0.5 | Yes |

V-2J | 92±1 | JET | 3.0±0.5 | 30±2 | 58±1 | ≤0.5 | Yes |

V-1JW | 93±1 | JET | 2.6±0.2 | 24±2 | 59±1 | ≤0.5 | Yes |

Company Introduction:

Packaging and shipping:

Package : 25kg PP bag/ Paper bag,.

500-1000kg/ton bag.

with pallet

Store in a dry and cool place. Stable storage for 5 years at room temperature.