- Victory

- China

- Quantity(Tons) 1 - 10 11 - 40 41 - 100 >100 Est. Time(days) 5 7 15 To be negotiated

- 2000T/Month

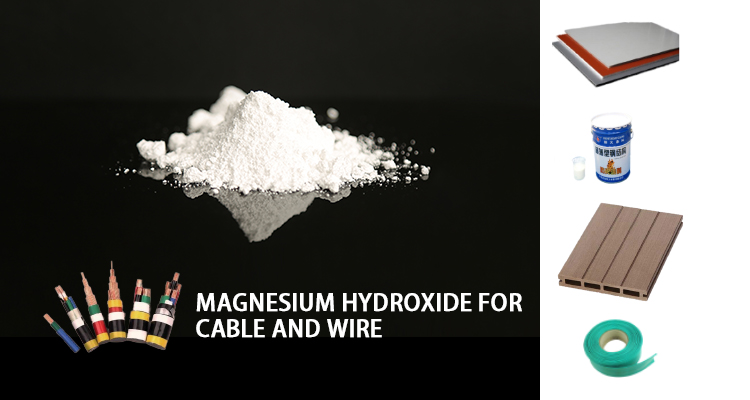

1. Magnesium hydroxide can be used alone or in combination with other flame retardants with excellent processing flow properties.

2.Magnesium hydroxide performs well in the formulation of other EVA wires.

3.Magnesium hydroxide can decompose non-toxic inert gas and decompose by heat at high temperature as additive.

4.Magnesium hydroxide has no poisonous gas, is good for environmental protection.

5.High processing temperature — more than 300°C.

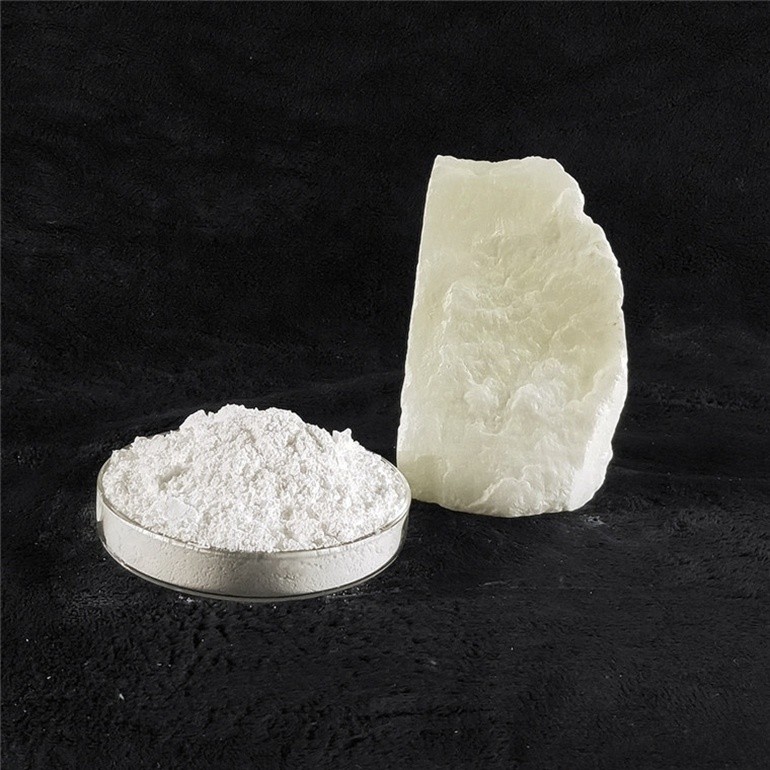

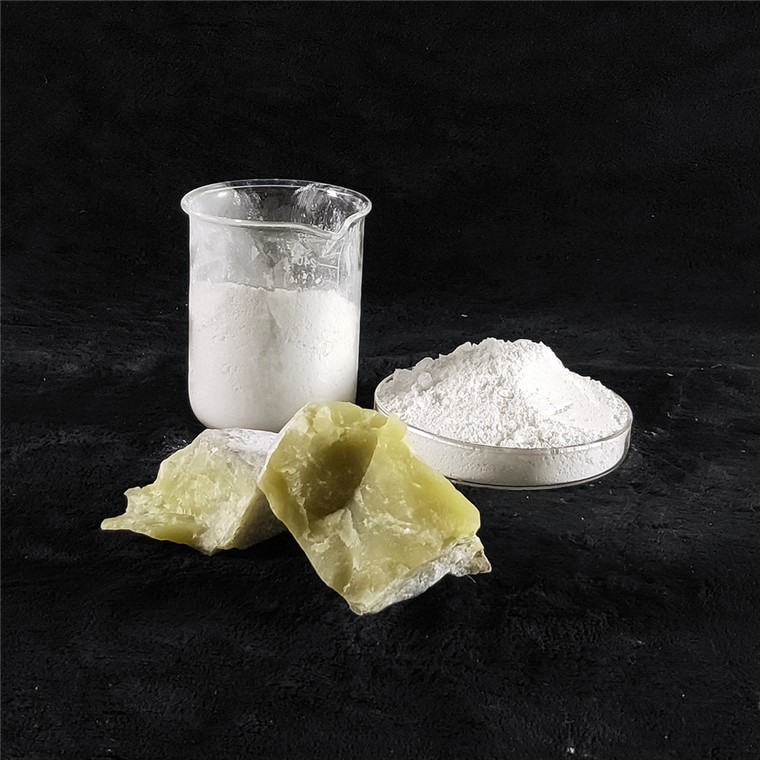

The Key Application of Magnesium Hydroxide in Cables is a natural mineral with good biocompatibility and little impact on the environment.

In water treatment, The investigation of using magnesium hydroxide can effectively adsorb heavy metal ions and organic pollutants to improve water quality.

As an alkaline substance, The investigation of using magnesium hydroxide can neutralize acidic substances and is suitable for the improvement of acidic soil and industrial wastewater treatment.

In some industrial applications, Magnesium Hydroxide for Wire Cable Compound can be used as an inhibitor to reduce the corrosiveness of other materials.

Compared with other chemical reagents, Magnesium Hydroxide for Wire Cable Compound is relatively safe and has low toxicity, making it suitable for a wide range of applications.

In medicine, magnesium hydroxide is often used as an antacid to help relieve discomfort caused by excessive gastric acid.

In addition to its applications in water treatment and medicine, Magnesium Hydroxide for Wire Cable Compound can also be used in fields such as plastics, rubber and building materials as a filler or flame retardant.

The Key Application of Magnesium Hydroxide in Cables Frost resistance of polyolefin compounds increase;

The Key Application of Magnesium Hydroxide in CablesProduction capacity of equipment increase;

The Key Application of Magnesium Hydroxide in CablesIt becomes possible to produce white compounds without additional colourants;

Magnesium Hydroxide GENERIC® FUSE®

Product | Test Item | |||||

Whiteness(%) | Production Equipment | Particle size D50(μm) | MgO(%) | Moisture(%) | Coated | |

V-1V | 91±1 | Vertical Mill | 4.5±0.5 | 58±1 | ≤0.5 | Yes |

VC-2V | 91±1 | Vertical Mill | 5±5 | 5 59±1 | ≤0.5 | Yes |

Product | Test Item | ||||||

Whiteness(%) | Production Equipment | Particle size D50(μm) | D100(um) | MgO(%) | Moisture(%) | Coated | |

V-1J | 92±1 | JET | 3.0±0.2 | 30±2 | 59±1 | ≤0.5 | Yes |

V-2J | 92±1 | JET | 3.0±0.5 | 30±2 | 58±1 | ≤0.5 | Yes |

V-1JW | 93±1 | JET | 2.6±0.2 | 24±2 | 59±1 | ≤0.5 | Yes |

Company Introduction:

With more ten years experience in fine machining of non-metallic minerals , We provide comprehensive customer service from the initial consultation to the final delivery of your order.

We always serves with enthusiasm and accepts full responsibility in customers' work. Our priority is your satisfaction and growing solid relationships with each of our customers.

As we are extending our buisness all over the word,we are looking forward to cooperating with you in the future.