- Victory

- China

- Quantity(Tons) 1 - 10 11 - 40 41 - 100 >100 Est. Time(days) 5 7 15 To be negotiated

- 2000T/Month

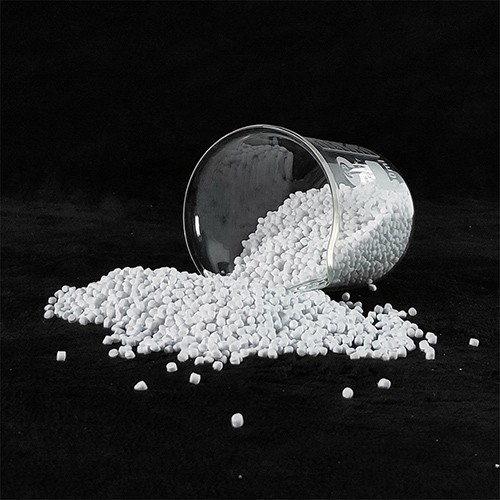

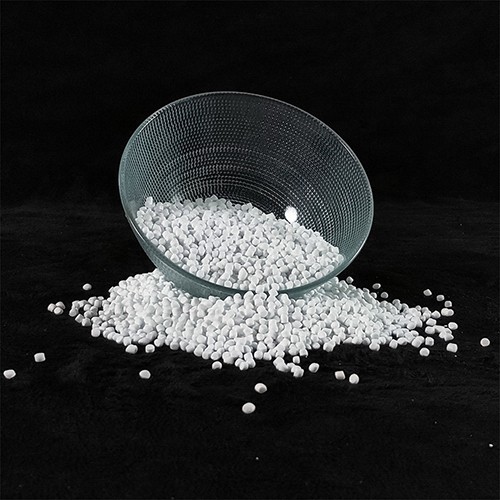

1.Calcium Carbonate Filler grades are granular and contain properties making them safe in pH adjustment, corrosion control and remineralization of reverse osmosis systems in water.

2.Calcium Carbonate Filler is widely used in thermoset applications. It is a key extender in fiberglass reinforced polyester applications such as Sheet Molding Compound (SMC) and Bulk Molding Compound (BMC) where it functions as a cost-effective extender with no adverse effects on processing or final physical properties.

3.Calcium Carbonate Filler has a high carrying capacity and allows powders to be reconstituted very easily.

4.Calcium Carbonate Filler has strong covering power and adhesion.

5.Calcium Carbonate Filler can improve the rheological property of the product and improve its formability.

CaCO3 Filler Masterbatch is widely used in plastic and rubber products, especially in flame retardancy. It has certain advantages, which are reflected in the following aspects:

Filler Calcium carbonate-Reduce costs: CaCO3 Filler Masterbatch is a cheaper filler that can significantly reduce production costs when added to plastics, especially when mass production is required. The economic benefits are obvious.

Filler Calcium carbonate-Enhanced flame retardant effect: CaCO3 Filler Masterbatch will decompose at high temperatures to generate carbon dioxide and calcium oxide. This decomposition reaction can absorb a large amount of heat, and the carbon dioxide released at the same time helps to dilute flammable gases, thereby achieving a flame retardant effect.

Filler Calcium carbonate-Improve processing performance: Powder Ground Calcium Carbonate usually has good fluidity and dispersion.Powder Ground Calcium Carbonate can improve the processing performance of plastic products, increase the surface finish and mechanical strength of the product, and is suitable for processes such as extrusion, injection molding and blow molding.

Filler Calcium carbonate-Good environmental performance: Powder Ground Calcium Carbonate itself is non-toxic and odorless, and is an environmentally friendly material. CaCO3 Filler Masterbatchdoes not produce harmful gases or toxic residues in the flame retardant system, so it is suitable for use in situations with high environmental requirements.

Filler Calcium carbonate-Improve material stability: Powder Ground Calcium Carbonate can enhance the thermal stability and mechanical properties of plastic substrates, thereby increasing the wear resistance, impact resistance and weather resistance of products, and helping to extend the service life of products.

Calcium carbonate masterbatch has broad application prospects in flame retardant composite materials, but CaCO3 Filler Masterbatch usually needs to be used in conjunction with other flame retardants such as aluminum hydroxide, magnesium hydroxide, etc. to obtain the best flame retardant effect.

Calcium carbonate GENERIC® FUSE®

| Product name | D50 (μm) | D97 (μm) | Specific surface area(㎡/cm³) | Sieve residue 45μm (%) | Oil absorption (gr/100gr) |

| V-N95 | 1.55~1.70 | 3.45~3.60 | 4.20~4.40 | <0.01 | 28~38 |

| V-N75 | 1.80~2.00 | 5.35~5.68 | 3.80~3.90 | <0.01 | 27~35 |

| V-N65 | 2.15~2.40 | 6.50~7.20 | 3.30~3.40 | <0.01 | 26~34 |

| V-N5 | 5.00~5.73 | 19.54~22.58 | 2.51~2.74 | <0.1 | 23~27 |

Company Introduction:

Business philosophy: quality-oriented, honesty

Corporate culture: sincerely believe, seek change and win, and people are better

Corporate Vision: Unleash the Unlimited Potential of Inorganic Mineral Powders