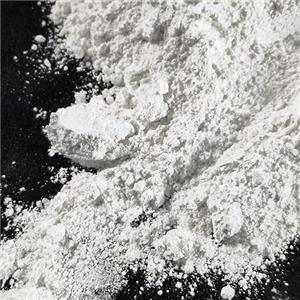

talc in plastics & polymers

-

Talc For Universal Plastic

1.Talc has good viscosity and other properties. 2.Talc has the advantage of high whiteness, uniform granularity and strong dispersibility. 3.Talc powder has good suspension and dispersability. 4.Talc an improve the toughness of the product. 5.Talc has high dimensional stability and chemical stability.

Email Details -

Hot

Talc Powder For Elastomer

1.Coating Grade 325-800 Mesh Talcum Powder can bend modulus and tensile yield strength of products. 2.Coating Grade 325-800 Mesh Talcum Powder can improve the mechanical properties of the products. 3.Talc in Rubber and Adhesive Industry has low abrasion resistance. 4.Talc in Rubber and Adhesive Industry improves UV radiation resistance and improves molding ability. 5.Talc in Rubber and Adhesive Industry has platy structure and organophilicity, talc represents a good modifier for elastomers enhancing rigidity and barrier properties.

Talc in Rubber and Adhesive Industry Talc in Plastics & Polymers Coating Grade 325-800 Mesh Talcum Powder Talc Powder For Talc Filled CompoundsEmail Details -

Talc Powder For Liquid Crystal Plastics

1.Talc can prevents high temperature creep. 2.Talc can improve dimensional stability in pipes and plates. 3.Talc can Improve the quality and appearance of home appliance products. 4.Talc can resistant to high temperature and color changing. 5.Talc has high dimensional stability and chemical stability.

Email Details