- Victory

- China

- Quantity(Tons) 1 - 10 11 - 40 41 - 100 >100 Est. Time(days) 5 7 15 To be negotiated

- 2000T/Month

1.Talc Powder For Plastic Industry can bend modulus and tensile yield strength of products.

2.Talc Powder For Plastic Industry has many kinds of application ,It can be added to food packaging plastics, especially meal boxes, plates, tableware, etc.

3.Talc Powder For Plastic Industry can Improve creep resistance in auto parts.

4.Talc filler in plastics can improve the thermal shock strength of the polymer.

5.Talc filler in plastics can corrosion resistance.

In the recycled plastics industry, the addition of Talcs For Recycled Plastic has multiple advantages and can significantly improve the performance and processing characteristics of recycled plastics. Recycled plastics are usually not as good as virgin plastics due to problems such as complex composition and reduced performance. Talcs For Recycled Plastic, as an important additive and filler, can help improve its overall performance. The following are the main advantages of Talcs For Recycled Plastic in the recycled plastics industry:

1. Talc filler in plastics can Improve the mechanical properties of recycled plastics

Recycled plastics are usually lower in strength, hardness and toughness than virgin plastics. talc plastic additive can effectively enhance the rigidity and strength of recycled plastics through its flaky structure, making them more impact-resistant and wear-resistant during use. talc plastic additive is very helpful for the production of low-cost plastic products, especially for scenes that require strength and durability, such as building materials, home appliance housings and industrial parts.

2.Talc filler in plastics can Improve dimensional stability and reduce warping

Due to multiple processing and uneven composition, recycled plastics are often prone to dimensional stability problems such as shrinkage and warping during the molding process. The low thermal expansion coefficient of Talcs For Recycled Plastic can effectively reduce the shrinkage and deformation of recycled plastics during thermal processing.Talc plastic additive can ensuring the dimensional accuracy and stability of the product, especially for large or high-precision plastic products.

3.Talc filler in plastics can Improve heat resistance

Adding Talc for plastic packaging can improve the heat resistance of recycled plastics, making them more stable under high temperature conditions and reducing thermal deformation. Talc for plastic packaging is especially beneficial for the production of products that require heat resistance, such as automotive parts and electrical housings.

Talc plastic additive is an economical filler that can significantly reduce material costs when added to recycled plastics. Talc plastic additive, as a cost-effective reinforcing filler, provides important support for the widespread application of recycled plastics.

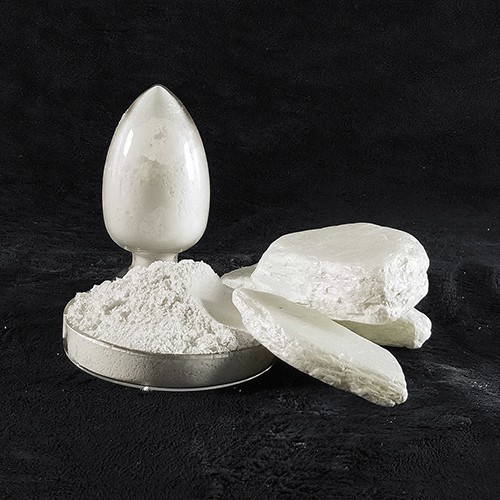

General Purpose Talc FUSE®

General-purpose talc is used for blended fillers in a wide range of fields, including the plastic, paper, rubber, paints, and ceramic application fields.

| Test Item | |||||||

| Product | Whiteness (%) | Particle size D50 (μm) | 45μm residue (%) | Moisture content (%) | Apparent density (g/ml) | Specific surface area (㎡/g) | Oil absorption (ml/100g) |

| F80-12 | 80 | 12 | 0.3 | 0.3 | 0.4 | 4.5 | 28 |

| F83-8 | 83 | 8 | 0.1 | 0.3 | 0.3 | 10 | 35 |

| F85 | 83 | 8 | 0.1 | 0.3 | 0.3 | 10 | 35 |

| F90-7 | 88 | 17 | 0.2 | 0.2 | 0.4 | 3.5 | 24 |

| F90-3 | 91 | 14 | 0.2 | 0.2 | 0.3 | 5 | 26 |

| F92-5 | 93 | 15 | 0.2 | 0.2 | 0.4 | 4 | 25 |

| F94-3 | 94 | 14 | 0.2 | 0.3 | 0.35 | 4 | 26 |

| F94-7 | 94 | 18 | 0.5 | 0.2 | 0.35 | 5.5 | 23 |

Our company operates with Japanese top production technology and scientific management,equipped with Japanese, German equipment and perfect testing instrument. We also pay attention to talent training and gradually established the independent research and development team.The company passed IS09001 quality system certification.Our products compiy with SGS,REACH and RoHS standard.