- Victory

- China

- Quantity(Tons) 1 - 10 11 - 40 41 - 100 >100 Est. Time(days) 5 7 15 To be negotiated

- 2000T/Month

1.Talc can improve the thermal shock strength of the polymer.

2.Talc can bend modulus and tensile yield strength of products.

3.Talc has high dimensional stability and chemical stability.

4.Talc's whiteness is enhanced after calcination.

5.Talc powder can increase the stiffness of plastic ester.

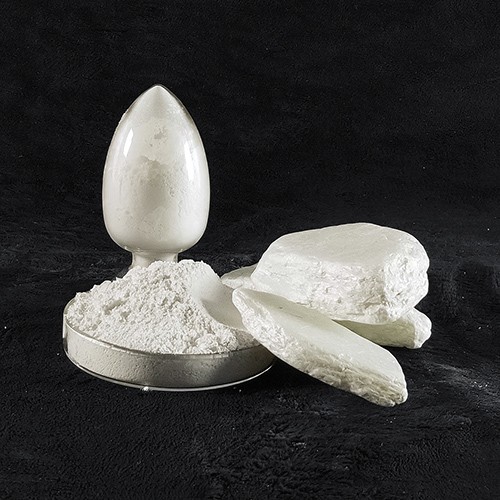

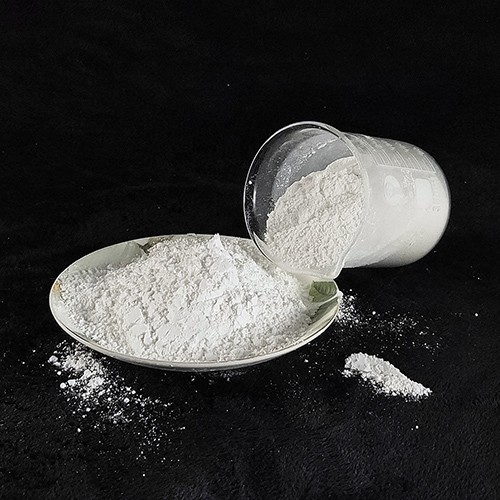

Talc is an additive, modifier or filler, widely used in a number of chemical industry, plastics and rubber in the modification of the application has a significant enhancement, can improve the tensile strength of plastic products, impact properties, creep resistance, heat resistance, tear-resistant and so on. can also improve the appearance of products, reduce product shrinkage to improve the barrier effect, reduce air permeability, increase the rigidity and stiffness of plastic products, has become the improvement of the physical properties of plastic products, more and more important to the plastics industry.

Talc can be widely used in PP, PE, PS, PA, ABS, PC, PVC and other resins. Talc in reducing the cost of plastic products at the same time, but also has significantly improved the rigidity of plastic products, heat resistance, creep resistance, reduce shrinkage and other advantages.

Talc powder can improve the pressure of the pipe, especially the ring stiffness is the important index restricting the large plastic pipe material, after adding a certain amount of talcum powder, it can obviously improve the ring stiffness of the plastic pipe, improve the product size stability, can improve the rigidity of the plate, flame retardant and chemical stability.

General Purpose Talc FUSE®

General-purpose talc is used for blended fillers in a wide range of fields, including the plastic, paper, rubber, paints, and ceramic application fields.

| Test Item | |||||||

| Product | Whiteness (%) | Particle size D50 (μm) | 45μm residue (%) | Moisture content (%) | Apparent density (g/ml) | Specific surface area (㎡/g) | Oil absorption (ml/100g) |

| F80-12 | 80 | 12 | 0.3 | 0.3 | 0.4 | 4.5 | 28 |

| F83-8 | 83 | 8 | 0.1 | 0.3 | 0.3 | 10 | 35 |

| F85 | 83 | 8 | 0.1 | 0.3 | 0.3 | 10 | 35 |

| F90-7 | 88 | 17 | 0.2 | 0.2 | 0.4 | 3.5 | 24 |

| F90-3 | 91 | 14 | 0.2 | 0.2 | 0.3 | 5 | 26 |

| F92-5 | 93 | 15 | 0.2 | 0.2 | 0.4 | 4 | 25 |

| F94-3 | 94 | 14 | 0.2 | 0.3 | 0.35 | 4 | 26 |

| F94-7 | 94 | 18 | 0.5 | 0.2 | 0.35 | 5.5 | 23 |