- Victory

- China

- Quantity(Tons) 1 - 10 11 - 40 41 - 100 >100 Est. Time(days) 5 7 15 To be negotiated

- 2000T/Month

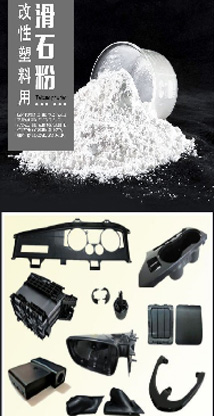

1.Talc for plastic modification can bend modulus and tensile yield strength of products.

2.Talc for plastic modification can resistant to high temperature and color changing.

3.Talc for plastic modification can corrosion resistance.

4.Talc Powder for Plastic Industry has high dimensional stability and chemical stability.

5.The whiteness of Talc Powder for Plastic Industry is enhanced after calcination.

First, Talc for polyolefins can significantly improve the rigidity and heat resistance of plastics. As a plastic modified filler, Talc for polyolefins is granulated by mixing with polymers or other carriers, which can significantly improve the stiffness, high-temperature creep resistance and heat resistance of the filling material.In addition, the addition of Talc for polyolefins can also increase the crystallinity of plastics, thereby enhancing the mechanical properties of plastics.

Secondly, Low odor Talc Powder can reduce the shrinkage of plastics. Studies have shown that the greater the Talc for polyolefins content, the smaller the molding shrinkage of the plastic. This is because Low odor Talc Powder, as an inorganic rigid material, has high stability and can effectively reduce the shrinkage of the plastic.At the same time, Low odor Talc Powder can also increase the crystallization rate of plastic blending systems and further reduce the shrinkage rate of plastic products.

Our company produces and sells all kinds of products instrict accordance with the international standard. With the rich experience, advanced research and development production technology,we not only assure the goods' quality but also improve the environmental benefits of products,to win the trustiness and support by the client all over the world.