- Victory

- China

- Quantity(Tons) 1 - 10 11 - 40 41 - 100 >100 Est. Time(days) 5 7 15 To be negotiated

- 2000T/Month

1.Talc Powder for Plastic Industry work as a insulation barrier in films.

2.Talc Powder for Plastic Industry can improve the rigidity of products, reduce shrinkage rate.

3.Talc Powder for Plastic Industry can improve dimensional stability in pipes and plates.

4.Talc Powder For General Plastics has some excellent physical and chemical properties,such as the lubricity, fire resistance, acid resistance, insulation, high melting point, good covering power and soft, good luster, strong adsorption force and etc.

5.Talc Powder For General Plastics can resistant to high temperature and color changing.

1.Modified Talc Powder is used in many industries such as paper making, plastic, paint and coatings, rubber, food, electric cable, pharmaceuticals, cosmetics, ceramics, etc.

2.Modified Talc Powder is a kind of inorganic filler with flame retardant, reinforcing various resin and compounding Fields: polypropylene (PP) compounding for automobile and the other composite plastics.

3.Modified Talc Powder has excellent dispersion and fluidity, which can improve the processing performance of plastics, coatings, rubber and other materials and enhance their processing efficiency. 4.the surface modification of Modified Talc Powder makes it excellent in enhancing the strength and toughness of materials, significantly improving the physical properties of products.

5.Talc Powder For Engineering Plastics can significantly improve the rigidity and strength of plastics.

6.Talc Powder For Engineering Plastics can enhance the mechanical properties of materials.

5.Talc Powder For General Plastics has good heat resistance and chemical stability make engineering plastics perform well in high temperatures and corrosive environments.

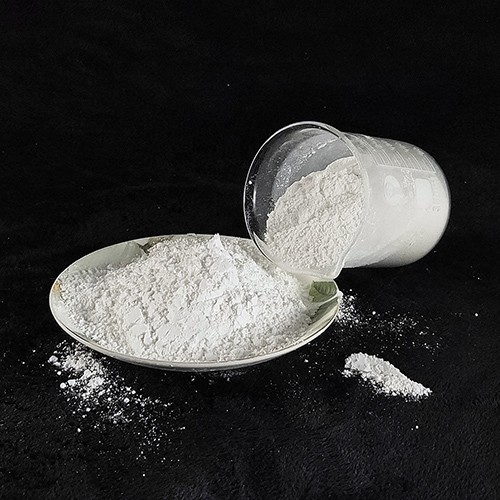

General Purpose Talc FUSE®

General-purpose talc is used for blended fillers in a wide range of fields, including the plastic, paper, rubber, paints, and ceramic application fields.

| FUSE® | |||||||

| Test Item | |||||||

| Product | Whiteness (%) | Particle size D50 (μm) | 45μm residue (%) | Moisture content (%) | Apparent density (g/ml) | Specific surface area (㎡/g) | Oil absorption (ml/100g) |

| F80-12 | 80 | 12 | 0.3 | 0.3 | 0.4 | 4.5 | 28 |

| F83-8 | 83 | 8 | 0.1 | 0.3 | 0.3 | 10 | 35 |

| F85 | 83 | 8 | 0.1 | 0.3 | 0.3 | 10 | 35 |

| F90-7 | 88 | 17 | 0.2 | 0.2 | 0.4 | 3.5 | 24 |

| F90-3 | 91 | 14 | 0.2 | 0.2 | 0.3 | 5 | 26 |

| F92-5 | 93 | 15 | 0.2 | 0.2 | 0.4 | 4 | 25 |

| F94-3 | 94 | 14 | 0.2 | 0.3 | 0.35 | 4 | 26 |

| F94-7 | 94 | 18 | 0.5 | 0.2 | 0.35 | 5.5 | 23 |

Packaging and shipping:

Package : 25kg PP bag/ Paper bag,.

500-1000kg/ton bag.

with pallet

Store in a dry and cool place. Stable storage for 5 years at room temperature.