- Victory

- China

- Quantity(Tons) 1 - 10 11 - 40 41 - 100 >100 Est. Time(days) 5 7 15 To be negotiated

- 2000T/Month

1.Non-halogenated Flame Retardants is environmental.

2.Non-halogenated Flame Retardants has moderate specific gravity, uniform particle size distribution.

3.Non-halogenated Flame Retardants have good dispersed liquidity,

4.Non-halogenated Flame Retardants in internal heat conduction reduces the ratio of component temperature.

Product Description:

In summary, magnesium hydroxide, as a halogen-free flame retardant, has become an ideal choice in more and more fields due to its environmental protection, high thermal stability, low smoke, low toxicity and other advantages, especially in applications requiring high safety. and environmentally friendly application scenarios.

Flame Retardant & Smoke Suppressant Additives have the following advantages over traditional halogen flame retardants:

Magnesium hydroxide Flame retardant-Better environmental protection: Plastics and Rubber Additivesdo not contain halogens (such as chlorine, bromine, etc.), so they will not produce harmful halide gases, such as dioxins or furans, when burned. These gases are harmful to the environment and human body, and Plastics and Rubber Additivescan greatly reduce the release of these harmful substances.

Magnesium hydroxide Flame retardant-Low smoke and low toxicity: Compared with halogenated flame retardants, Flame Retardant & Smoke Suppressant Additives generally produce less smoke and toxic gases when burned. This is especially important in fires, where smoke and toxic gases are one of the leading causes of casualties.

Magnesium hydroxide Flame retardant-Better thermal stability: Non-halogenated antimony flame retardants generally have better thermal stability and can remain stable at higher temperatures and are not prone to decomposition or volatilization. Flame Retardant & Smoke Suppressant Additives makes it perform well in high-temperature environments and is especially suitable for some high-temperature processes and products.

Magnesium hydroxide Flame retardant-Comply with environmental regulations: As environmental regulations around the world become increasingly stringent (such as the EU's RoHS directive), non-halogen flame retardants, Plastics and Rubber Additives,due to their environmental advantages, can better comply with the requirements of these regulations and reduce potential harm to the environment and human health. .

Magnesium hydroxide Flame retardant-Non-corrosive: Traditional Plastics and Rubber Additives may release corrosive gases, such as hydrogen chloride or hydrogen bromide, when burned, which may cause damage to electrical equipment or other sensitive materials.Flame Retardant & Smoke Suppressant Additives do not have this problem and are more suitable for use in electronic and electrical applications that require corrosive materials.

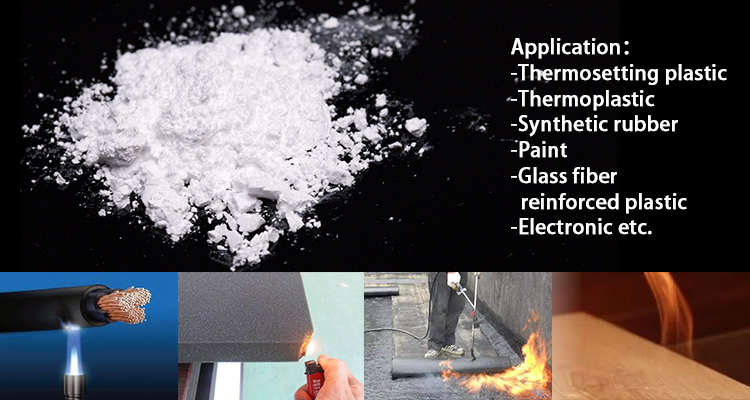

Magnesium hydroxide Flame retardant-Wide applicability: Plastics and Rubber Additives are suitable for various polymers and materials, especially in areas with high environmental protection and health requirements such as electronics, electrical appliances, automobiles, and construction.

In general, Plastics and Rubber Additives not only perform well in performance, but also have obvious advantages in environmental protection, safety and regulatory compliance, so they are gradually replacing traditional halogenated flame retardants in the market.

Quality Index

Appearance: white powder

Bromine content: 10%

Nitrogen content: 18%

Phosphorus content: 28% Loss on drying ≤ 0.3%

Start decomposition temperature: 285 ° C

Solubility: insoluble in water, alcohol, alkanes, naphthenes, etc., soluble in dichloroethane, toluene, acetone, esters and so on.

Highly efficient flame retardant is a new and efficient reaction type of environmentally friendly P, N, Br composite flame retardant.

Has the following advantages:

This carbon layer can effectively block heat transfer and combustible contact with air while suppressing the generation of smoke Do not produce hydrogen chloride and other corrosive gases), which play a flame retardant, smoke suppression effect.

This product is white powder phosphine nitrogen flame retardant, nitrogen phosphine content is high (P ≥ 20%).environmentally friendly halogen-free, in line with the EU ROHS standards,high thermal stability (> 320 ℃), fully meet the molding processing temperature requirements.

Excellent flame retardant effect, add 14-17% flame retardant, 25-30% glass fiber, can easily reach V0 (1.6MM) level, with CTl value (compared to trace index) about 600V good electrical performance.

Fire retardant material GENERIC® FUSE®

| Formula | 1# | 2# | 3# | 4# | |

| Homogeneous PP(MI 10) | 99 | / | / | / | |

| Homogeneous PP(MI 0.3) | / | 98 | / | / | |

| PP(MI 3)+20% Talcum powder | / | / | 98 | / | |

| PP(MI 3)+35%Barium sulfate | / | / | / | 98 | |

| Flame retardant TMF-066FR | 1 | 2 | 2 | 2 | |

| Flame retardant properties | LOI(%) | 27 | 25 | 24 | 25 |

| UL-94(3.2mm) | V2 | V2 | V2 | V2 | |

| UL-94(1.6mm) | V2 | V2 | V2 | V2 | |

Our guarantee as below:

1) Goods quality will be same as samples, COA which supplied to you firstly.

2) Package also could be done accordingly to customer's request, safe and good look. Conform to standard of dangerous goods shipment. And photos will be taken during the process of container load, which will be supplied to each customers.

3) Shipment will be done by us, booking the direct, non-transfer vessel for prompt shipment. And shipping details will be advised.

4) After vessel left, the full set shipping documents will be scanned & delivered to you on time.

5) Any issues after picking up goods or during the usage, please contact us without hesitation.