- Victory

- China

- Quantity(Tons) 1 - 10 11 - 40 41 - 100 >100 Est. Time(days) 5 7 15 To be negotiated

- 2000T/Month

1.Magnesium hydroxide can improve the surface and mechanical properties of copper clad laminate.

2.Magnesium hydroxide performs well in the formulation of other EVA wires.

3.Magnesium Hydroxide is suitable for high temperature process of the flame – retardant rubber and plastic.

Magnesium hydroxide has unique buffering and neutralization capability.

4.Magnesium hydroxide has good heat resistance, temperature, good compatibility of resin.

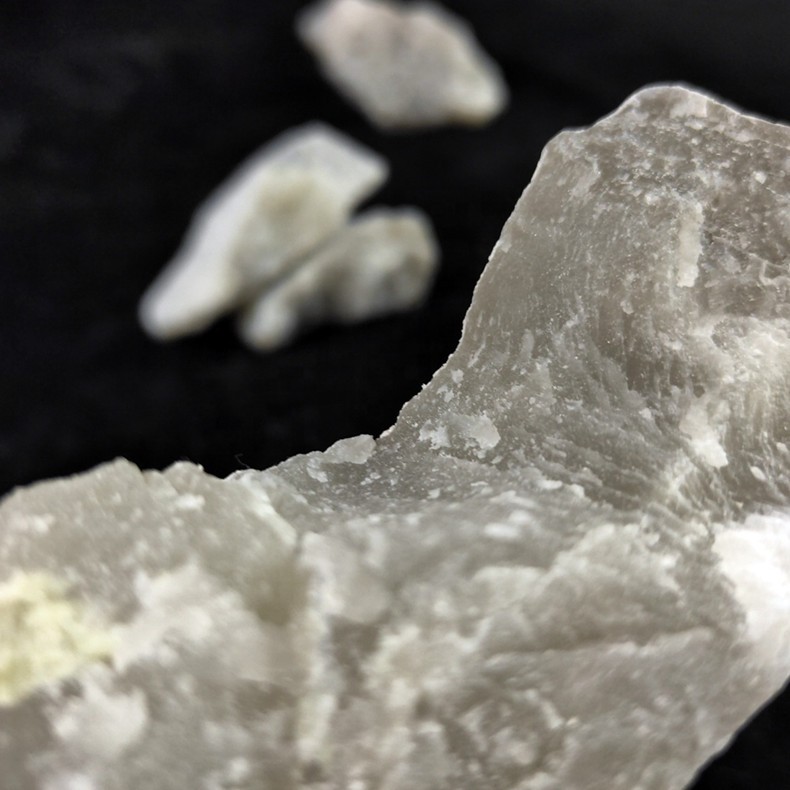

5.brucite mineral can be easily applied in various polymer compositions based on different polymeric matrix (PE, EVA, PP, PVC, PA) using advanced processing techniques ( such as extrusion, molding under pressure.

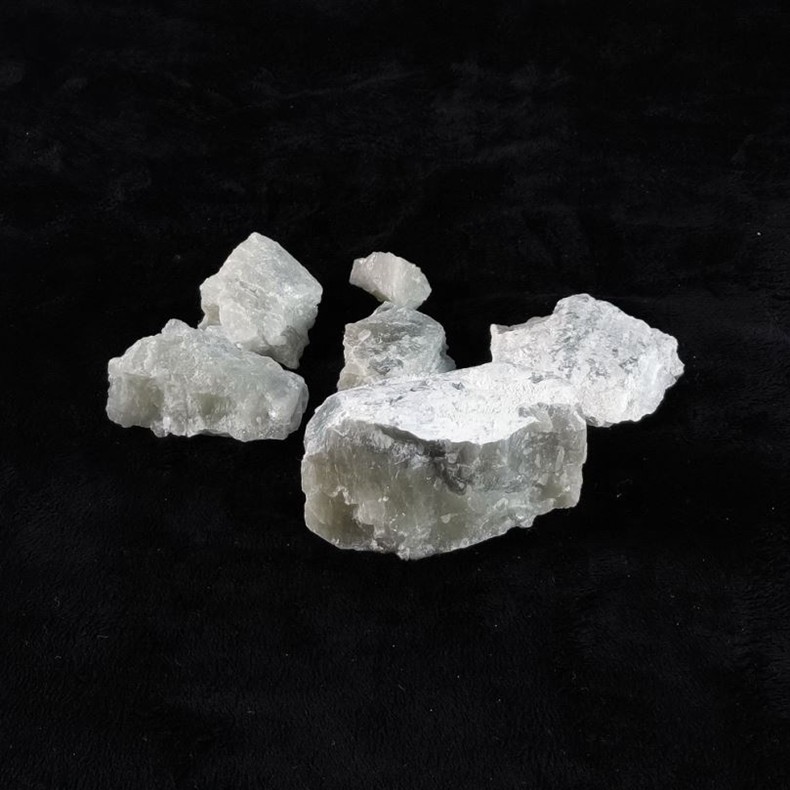

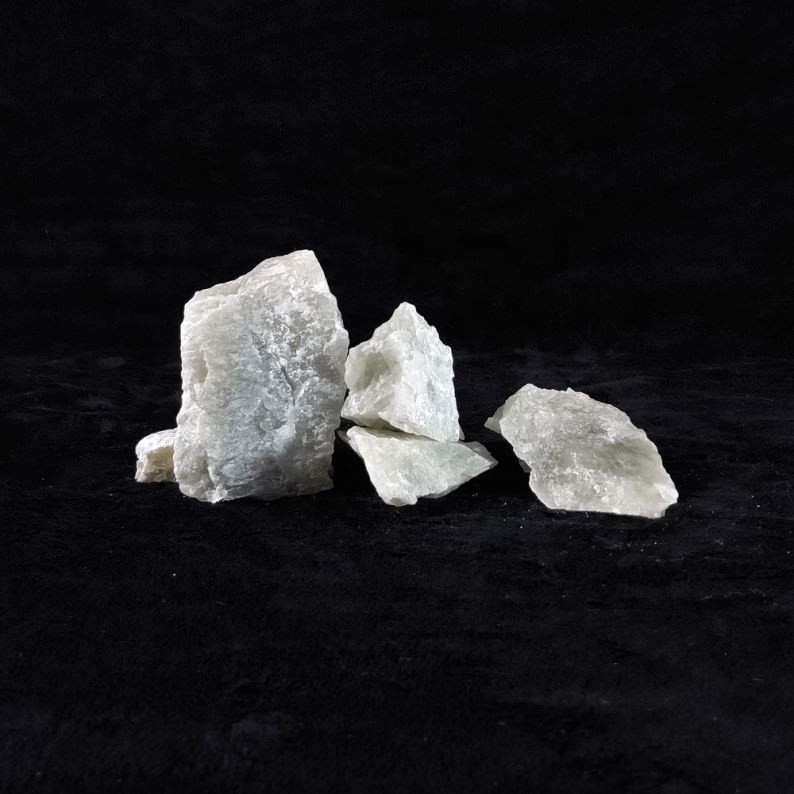

1.Technical Grade Brucite-Chemical stability

Brucite has strong chemical stability, is not easy to react chemically at room temperature, and is insoluble in water. Therefore, it remains stable in a variety of application environments and is not easy to degrade or corrode.

2.Technical Grade Brucite-Wide range of applications

Plastic and rubber industry: brucite mineral is widely used in flame-retardant plastics and rubber products, especially in wires and cables, automotive parts and other occasions that require high flame retardancy.

Building materials: Due to its good flame retardancy and low smoke properties, brucite mineral is often used in the production of fireproof building materials, such as fireproof boards, thermal insulation materials, etc.

Environmental protection: brucite mineral can also be used as a neutralizer for the treatment of industrial wastewater, adsorption and desulfurization of acidic gases, etc.

3.Technical Grade Brucite-Processability

Brucite particles are fine and well dispersed. They are easy to mix and process with other materials without affecting the physical properties and processing properties of the base material. brucite mineral are suitable for large-scale industrial applications.

4.Technical Grade Brucite-Cost-effectiveness

brucite mineral has relatively low mining and processing costs, especially in some fields that are sensitive to material costs (such as construction and plastics). It provides a cost-effective option.

Summary

Brucite has become an ideal functional additive in many industries due to its good flame retardancy, thermal stability, environmental protection and wide application prospects. Especially in the fields of plastics, rubber, building materials, etc.brucite mineral advantages enable it to meet the fire protection needs while also having environmental protection, health and economic benefits.

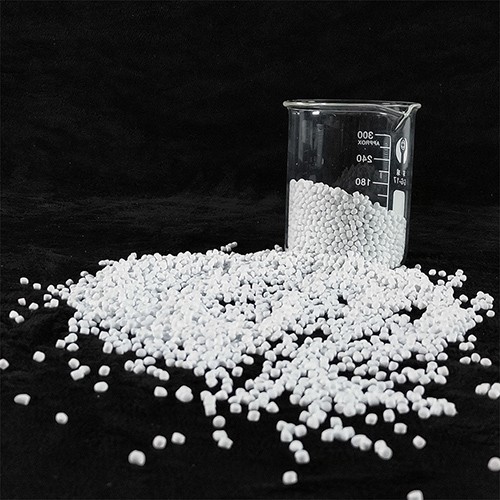

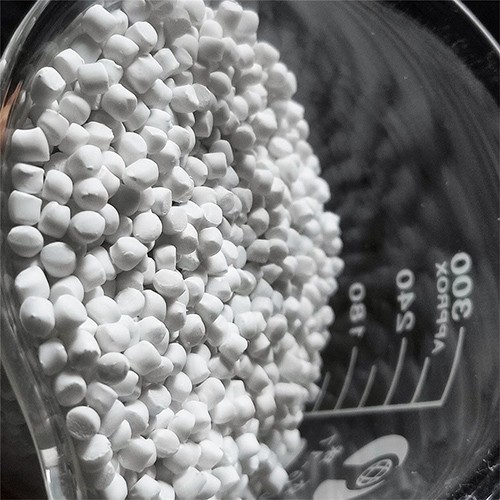

Magnesium Hydroxide GENERIC® FUSE®

| Test Item | ||||||

| Product | Whiteness(%) Hunter method | Production Equipment | Particle size D50(μm) Laser diffraction | MgO(%) | Moisture(%) | Coated |

| V-1V | 91±1 | Vertical Mill | 4.5±0.5 | 58±1 | ≤0.5 | Yes |

| VC-2V | 91±1 | Vertical Mill | 5±5 | 59±1 | ≤0.5 | Yes |

Company Introduction:

Founded in 2019, the comapmy is a global supplier of halogen-free flame retardant material and Nonmetallic ultrafine nano-powder.

We are a comprehensive company intergrating R&D, productoion and sales, have more than 200 employees and opreate oversea, producing in own mines, serving more than hundred customers including the world’s top 500 enterprises in Europe, Japan, South Korea and Sourheast Asia.

we are committed to providing for domestic and foreign customers with high quality and high technology products and services in related application industries.