Worth collecting! What are the methods for purifying talc?

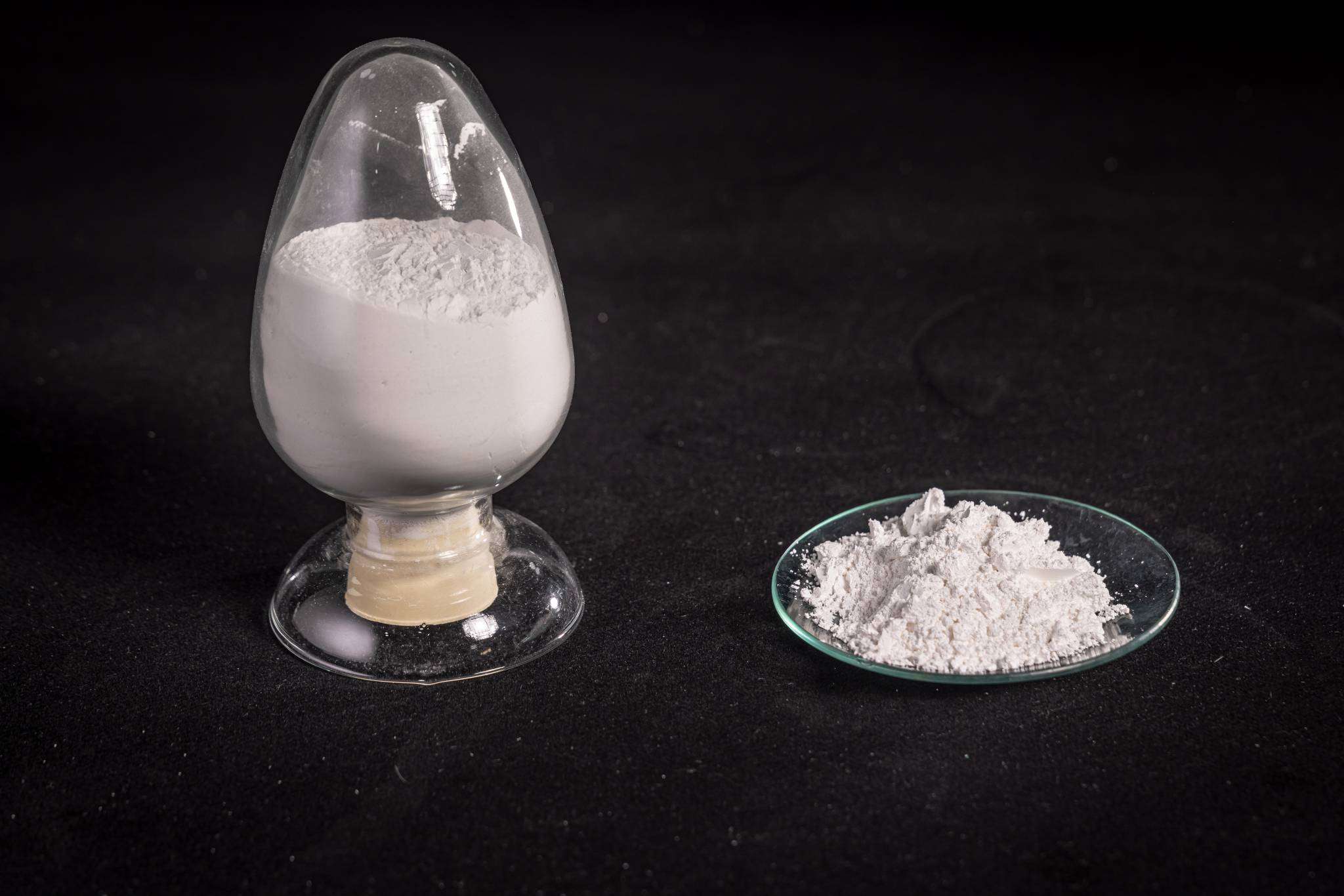

Talc is a common hydrothermal alteration mineral that is widely used in ceramics, medicine, cosmetics, rubber and other fields. However, talc ore usually contains associated minerals such as dolomite, calcite, quartz, etc. These impurities can significantly reduce the purity and application performance of talc. Therefore, the efficient purification of talc ore is particularly important.

Talc purification method

According to the different characteristics of talc ore, a variety of purification processes have been researched and developed, each with unique advantages and applicable scenarios.

Flotation

Flotation is the most widely used method in talc purification. Because talc has natural buoyancy, it can be flotated using hydrocarbon oil collectors (such as kerosene and flotation oil). The process usually includes one rough separation, one sweep and two to four times of concentration to obtain high-purity concentrate. The flotation method is simple to operate and highly efficient, and is suitable for the purification needs of most talc ores.

Hand selection method

The hand selection method is based on the difference in smoothness between talc and gangue minerals. Since talc is smooth to the touch and of high grade, massive associated minerals can be removed through manual identification. However, the manual selection method has low efficiency and requires high operator experience. It has been gradually replaced by advanced technologies such as photoelectric color sorting.

Photoelectric color sorting method

The photoelectric color sorting method uses the property of talc to emit white fluorescence under ultraviolet light, and separates talc from impurities through a color sorter. Color sorting equipment consists of raw material bins, feeders, conveyor belts, radiation sources and detectors, etc., and has the characteristics of high precision and efficiency. For example, the American Cyprus Talc Company uses this method to upgrade poor ore with a talc content of 30% to rich ore with a talc content of 69%. After further processing, it finally obtains cosmetic grade talc with a purity of up to 99%.

Magnetic separation

The magnetic separation method uses the magnetic differences between talc and associated minerals to separate impurities through magnetic separation equipment. This method is mainly used to remove siderite, pyrite, tremolite and other magnetic minerals, and can significantly improve the whiteness and purity of talc. Research shows that after optimizing the magnetic separation process, the iron content in talc concentrate can be reduced from 4% to 5% to less than 1%.

Scrub method

The scrubbing method separates talc and impurities by adding acids or chemicals to the water and utilizing the differences in solubility and sedimentation speed in the water. Although the cost of the scrubbing method is low, the recovery rate is low due to the small difference in specific gravity between talc and associated minerals, which can easily lead to the loss of talc.

Electric selection method

The electroseparation method is based on the difference in electrical conductivity between talc and gangue minerals, and is separated in a high-voltage electric field. This method is suitable for roughing and concentrating talc and tailings sweeping. Commonly used technologies include frictional electrification separation, high gradient separation and dielectric separation.

Chemical treatment

Chemical treatment method uses hydrochloric acid, bleach and other chemicals to treat talc ore to remove calcium carbonate, quartz particles and iron-containing impurities to improve the whiteness of talc. Commonly used methods include acidification, crystallization purification and drying processes, which can be used to prepare high-purity ultra-fine talc powder.

Selective flocculation

The selective flocculation method uses chemicals to flocculate talc particles to separate them from impurities. This method is often used as a pretreatment step before flotation and is suitable for the purification of low-grade talc ore to further improve the purity of the mineral.

Calcination method

The calcination method heats talc at a high temperature of 1200~1300°C to remove carbon-containing impurities such as graphite schist and improve the whiteness and activity of the talc. This method has a significant effect on treating black talc and can also improve the physical and chemical properties of talc.

Summarize

There are many types of talc purification processes, each with its own advantages and limitations. In practical applications, a variety of purification technologies should be used comprehensively based on the specific characteristics of talc ore to achieve low-cost, high-efficiency purification goals. A reasonable purification process can not only improve the purity and performance of talc, but also significantly expand its application scope in various fields.