Why add talcum powder to plastics and precautions

As a common inorganic filler, Plastic Grade Talcum Powder is widely used in plastic modification, which can significantly improve the physical properties of plastics and reduce production costs. Research by foreign scholars shows that Pure Talc Powder has stable performance and broad application prospects. The following is a detailed discussion of the performance and application value of talc powder in plastic modification:

1. Performance of talc powder in plastic modification

Molding shrinkage

Plastic Grade Talcum Powder can effectively reduce the molding shrinkage of plastics. Research shows that the higher the Pure Talc Powder content, the smaller the molding shrinkage of the plastic. This is because Plastic Grade Talcum Powder, as an inorganic rigid material, has an extremely low shrinkage rate, which can increase the crystallization rate of plastics and reduce the overall shrinkage of plastic products.

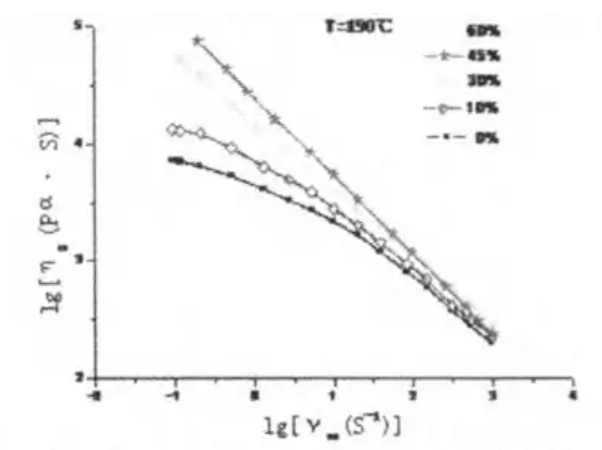

Processing performance

Plastic Grade Talcum Powder content can affect the processing properties of plastics. After filling with Pure Talc Powder, the rigidity and dimensional stability of the material are improved, but the fluidity is reduced. As the Pure Talc Powder content increases, the viscosity of the system increases, especially at low shear rates; while at high shear rates, the viscosity increase is less significant.

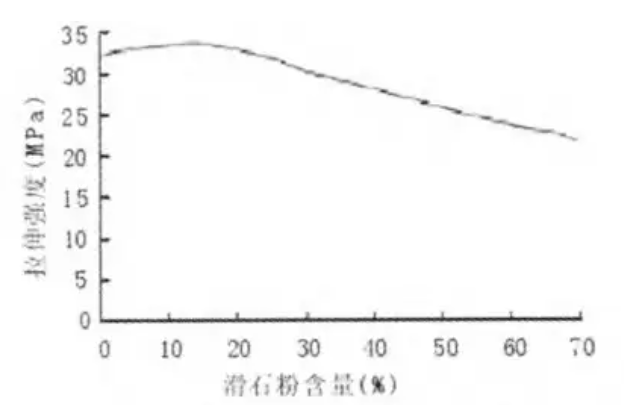

tensile strength

Plastic Grade Talcum Powder has a certain impact on the tensile strength of plastics. When the Pure Talc Powder content is 0-15%, the tensile strength of the plastic increases as the content increases. However, when the Pure Talc Powder content exceeds 15%, the tensile strength decreases. This is because when the content is low, talc can increase the crystallinity of the plastic, thereby enhancing the strength; but when the content is too high, the discontinuity of the material increases and the binding force between plastic molecules weakens, resulting in a decrease in tensile strength.

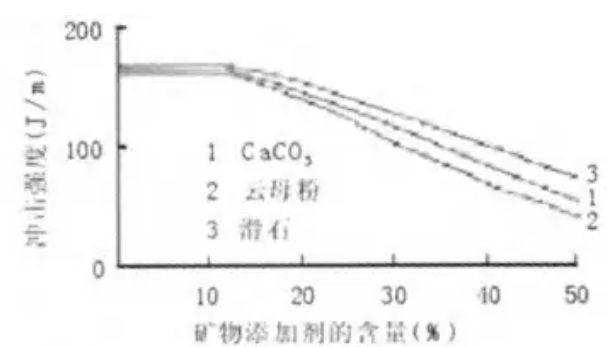

Impact strength

The talc content also affects the impact strength of the plastic. When the talc content is 0-10%, the impact strength is basically unaffected; but when the content exceeds 10%, the higher the talc content, the lower the impact strength of the plastic. This may be due to the fact that talc increases the brittleness of the material, thereby reducing the impact strength.

Deformation temperature

Talc can increase the deformation temperature of plastics. Since Pure Talc Powder has good heat resistance, the thermal deformation temperature of plastic products will increase after adding talc powder. The higher the talc content, the more significant the heat resistance and deformation temperature of plastic products increase.

2. Application value of talc powder in plastics

Reduce costs

Compared with plastic raw materials, the price of Plastic Grade Talcum Powder is relatively low. Especially in the context of rising plastic prices, using talc powder for filling can significantly reduce production costs and improve the economic benefits of enterprises.

Improve plastic properties

Plastic Grade Talcum Powder can effectively improve the physical properties of plastics, such as rigidity, tensile strength, heat resistance, etc. This not only expands the application scope of plastics, but also enables modified plastics to meet more market needs, especially in the field of high-performance materials.

In summary, the application of talc powder in plastic modification has many advantages. By rationally selecting the content and filling method of talc powder, the molding shrinkage, processing performance, mechanical properties and heat resistance of plastics can be effectively improved, while production costs can be reduced, making it widely used in industrial production.