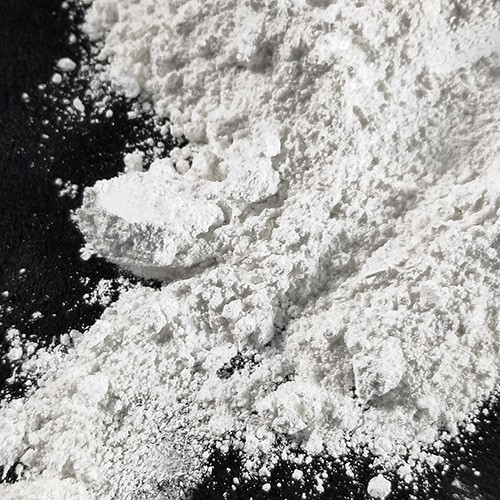

The application of Talc Powder in Coatings

Talc Powder for industrial paints has good suspensibility, easy dispersion and low corrosivity. In the coating, talcum powder as filler can play the role of skeleton, reduce the manufacturing cost and improve the film hardness of the coating.

It also has the characteristics of improving the stability of product shape, increasing tension strength, shear strength, pressure strength, reducing deformation, elongation, coefficient of thermal expansion, high whiteness, strong uniform dispersion of particle size and so on.

The talcum powder with flake particle structure can make the film have high water resistance and impermeability of enamel, while the talcum powder with fibrous particle structure can improve the rheology and leveling of the coating, and improve the weather resistance of the coating at the same time.

Specific performance characteristics and applications:

1.Talc For Coating can improve the adhesion and solvent resistance: ultra-fine talc powder can improve the adhesion and solvent resistance of some difficult substrates such as polished aluminum and stainless steel in different coatings such as solvent-based wood coatings and waterborne coatings.

2.Talc Powder For coating can improve the processing performance of the coating: when ultra-fine talc powder is used in waterborne latex paint, it can give latex paint good brushing, leveling and gloss retention, and the obtained coating has good impact resistance and flexibility, and can effectively improve the corrosion resistance and dryness of the coating. Talc powder can improve the fillability of the coating and prevent cracks in the film. Because of the low hardness of talc powder, it also helps to improve the grindability of the film.

3. Improve the heat resistance of the heat resistant coating: some studies have shown that the epoxy silicone high temperature resistant coating is prepared with talc powder as the main filler and epoxy modified silicone resin as the base material. talc powder can increase the high temperature adhesion of the coating.

4. Used for coating reinforcement: because talc powder for coating has a special layered structure and large diameter-thickness ratio, when it is added to polyurethane, when the content is small, it can effectively prevent the crack propagation of polyurethane under stress, play the role of stress concentration point, and improve the tensile strength.