The application of magnesium hydroxide flame retardant in cable material

With the continuous expansion of the application field of polymer materials, flame retardant technology has also attracted increasing attention. Since the 1970s, flame retardants have become the fine chemicals second only to plasticizers in the amount of plastic and rubber additives. In recent years, developed countries in the United States, Japan and Europe have maintained a high rate of growth, the current practical application of a wide variety of flame retardants, mainly halogen, organophosphorus, phosphate-nitrogen, silicone and inorganic aluminum series, magnesium series, boron series, antimony series, molybdenum series, tin series, etc. Among them, halogen series (focusing on bromine series) flame retardants are currently the world's largest production and consumption of organic flame retardants, but the use of synthetic materials of organic flame retardants, in the fire emitted toxic gases and smoke, so that the visibility of the fire site is low, causing serious difficulties to the fire and rescue, and even people, livestock poisoning death.

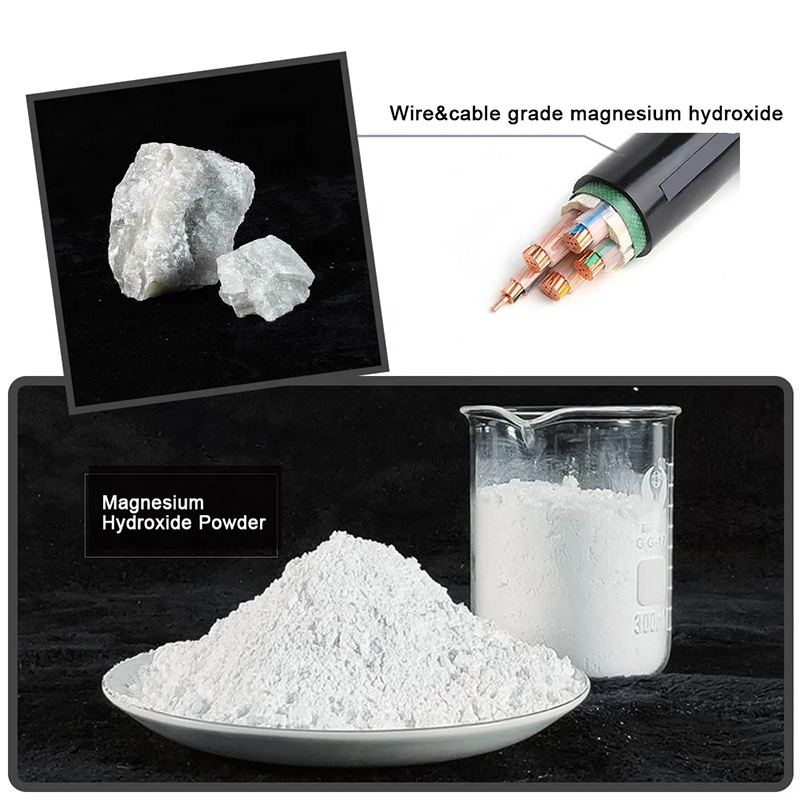

Due to the high price of organic flame retardants, its application is also limited. Especially in Europe, due to pressure from environmental protection organizations, halogenated flame retardants are decreasing at a rate of 3% year by year.Magnesium hydroxide is currently being promoted as a pollution-free inorganic flame retardant, which has no harmful substance emissions in the production, use and waste process, does not affect the electrical insulation of the resin, and can also neutralize the acidic and corrosive gases generated in the combustion process, and is an environmentally friendly green flame retardant.

At present, developed countries such as Europe, the United States and Japan have strictly prohibited the use or import of non-environmentally friendly cables. The European Union in the RoHs directive stipulates that electrical equipment products placed on the market can not contain lead, mercury, cadmium, hexavalent chromium, polybrominated diphenyl ethers, polybrominated biphenyls and other six harmful substances. The ROHS directive has also had a great impact on the cable material industry, especially for flame-retardant cable materials, which put higher requirements on the environmental protection of flame retardants and other additives used in their processing formulas. Wire and cable in the production and use process, the impact on the environment is more and more attention by the industry, at present, Switzerland, Germany, Sweden, the United States, Japan and other countries, the production and use of cable material products have formulated strict laws, and limit and will eventually eliminate PVC in the wire and cable industry application.

In recent years, as people's performance requirements for cable materials are getting higher and higher, a variety of high-performance, environmental protection, flame retardant cable materials have been continuously developed, whether at home or abroad, halogen-free wire and cable development direction, the market prospects are very broad, with great market potential.