Must remember! 9 standards for using talcum powder in plastics!

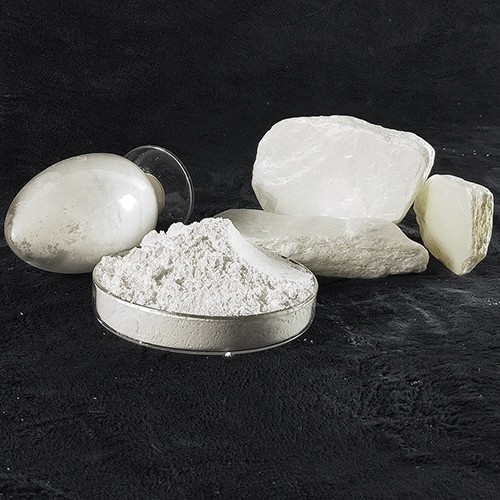

Talc Powder for Plastic Industry is one of the most widely used inorganic powders in plastic products. The characteristic of Talc Powder for Plastic Industry is that it can significantly improve certain properties of plastic products. Therefore, when choosing Talc Powder for Plastic Industry, the following requirements should also be met.

High purity

The higher the purity of Low odor Talc Powder, the better its reinforcing effect. Among other mineral impurities in talcum powder, metal minerals (especially iron) have a very obvious effect on the anti-aging properties of plastics.

Structure

Low odor Talc Powder usually has a layered crystal structure, which gives it good lubricity. High-quality ultrafine talcum powder has a flaky structure and can be evenly dispersed in plastics to enhance the mechanical properties of plastics. It can improve the physical properties of plastics and play a role in heat preservation and heat insulation.

Just like a metal structure mesh embedded in cement products, while maintaining the advantages of the plastic itself, it forms an enhanced support form with excellent mechanical properties, which can improve the physical properties of plastic products. At the same time, it also has obvious heat preservation and barrier effects, while reducing production costs, it improves the physical properties of plastic products.

Wet whiteness and hue

After Low odor Talc Powder is mixed with plastic, the color of the plastic will change more or less. Dark plastic products do not require high whiteness of talcum powder, but in order to make light-colored products have a better hue, Low odor Talc Powder must have a higher wet whiteness and a suitable hue.

Silica content

The silica (SiO2) content in Talc for plastic modification is a key indicator of its purity. The higher the silicon content, the better the quality and application effect of the talc, but the price is also relatively high. Different plastic products have different requirements for silicon content. For example, agricultural films require a higher silicon content to improve the light transmittance and strength of the film.

Color

Unprocessed Talc for plastic modification ore has a variety of colors, from white to gray, red, pink, blue, etc., and even silver or pearl colors, which can improve the appearance and visual effects of plastic products.

Surface properties

Talc has different surface properties depending on its source. The specific surface area and oil absorption rate depend largely on the mineral resources and product fineness. Other factors that affect these properties include surface roughness, particle shape and pore volume. The larger specific surface area and appearance structure of talc not only affect the amount of additives, but also promote the bonding force between resin structures, thereby improving the physical properties of plastic products.

Moisture content

Talc for plastic modification has a high moisture content.Talc for plastic modification is may affect the performance of plastics, so its moisture removal and drying process are crucial.

Static electricity

Talc for plastic modification has a layered structure and a large specific surface area. The irregular shape of the particles and the convex and concave morphology of the surface make its friction coefficient large, which is easy to generate static electricity, causing the aggregation of tiny particles, making it difficult to disperse, and affecting the application effect.

Flowability

The flaky structure of Talc for plastic modification makes it have poor flowability and dispersibility during extrusion, which may increase the torque during extrusion. Therefore, improving the activation and coating technology of Talc Powder for Plastic Industry is the key to solving these problems.