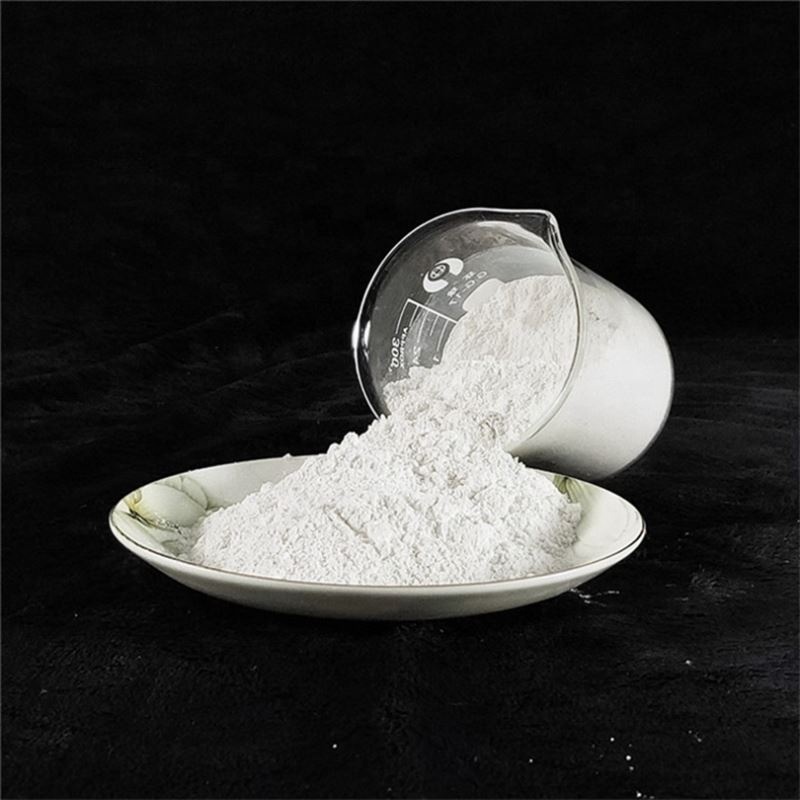

Let’s take a look at 5 examples of surface modification of talc

1. Titanate coupling agent modification of talc powder

The titanate coupling agent changes its hydrophilic properties by forming a single-molecule covering film on the surface of talc powder, thereby causing fundamental changes in the surface properties of the filler. Due to its special molecular structure, titanate coupling agents can significantly improve the coupling efficiency of polymers and fillers, thereby enhancing the dispersion and fluidity of fillers, while improving the elongation at break, impact properties and resistance of composite materials. combustion performance.

(1) Modification method

Dry modification: Place the talc powder in a high-speed mixer preheated to 100℃-110℃, stir and dry, then add proportionally diluted titanate coupling agent (using 15# white oil as diluent). Stir for a few minutes to obtain the modified talc filler.

Wet modification: Dilute the measured titanate coupling agent with an appropriate amount of solvent, mix it with talc powder, stir at 95°C for 30 minutes, then filter and dry to prepare modified talc powder.

(2) Application characteristics

Talc powder modified by titanate coupling agent can effectively improve the compatibility with polypropylene (PP), reduce the viscosity of the system, improve fluidity and processing performance, and at the same time improve the dimensional stability of the material, reduce deformation, and expand the Its application fields in PP.