Introduction to the seven application areas of ultrafine talcum powder-2

Application in polypropylene resin

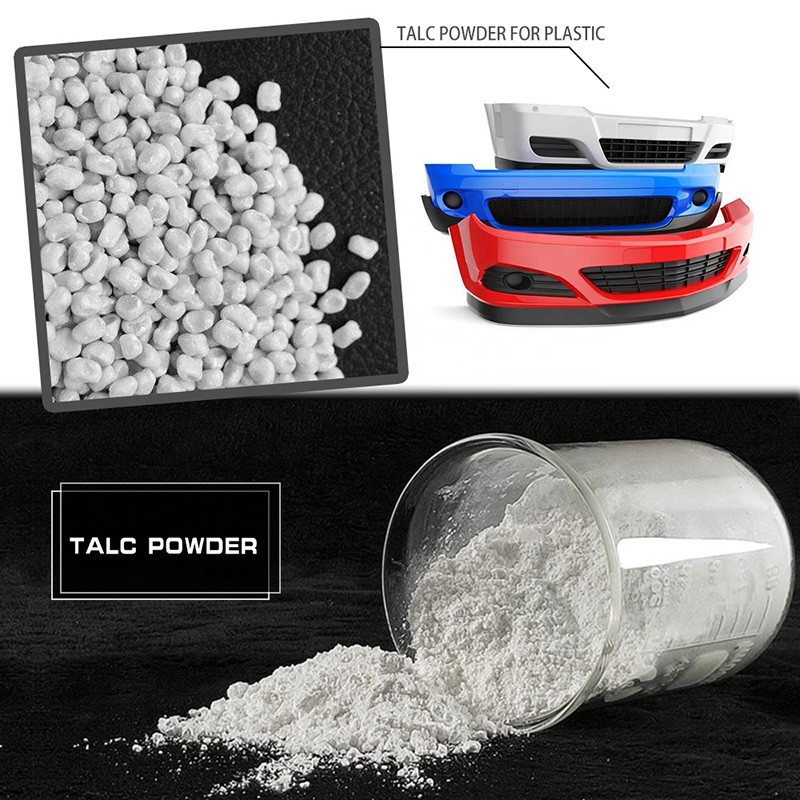

Talcum powder is often used as a reinforcing filler in polypropylene due to its flaky structure. Adding ultrafine Talcum powder can significantly improve the rigidity, surface hardness, heat resistance, electrical insulation and dimensional stability of polypropylene, while enhancing impact strength. Polypropylene filled with 20%-40% talc is widely used in bumpers, dashboards, fan covers and other components in the automotive industry, in the aviation industry for refrigerator door gaskets, heater covers, etc.; in the electrical and home appliance industries It is used in injection molded products such as instrument casings and washing machine inner barrels.

Application in polyethylene resin

The microscale structure of Talcum powder gives it good chemical resistance and sliding properties, and filling it with polyethylene can improve toughness, strength, dimensional stability, creep resistance and thermal properties. Adding 10%-15% talcum powder has the best effect and is suitable for film blowing process. The film produced has excellent moisture resistance and oxygen barrier properties, and is suitable for packaging food and geotextile applications.

Application in ABS resin

ABS is an amorphous polymer that is filled with ultra-fine Talcum powder to improve its impact resistance, low temperature resistance and creep resistance, and reduce costs. Its modified ABS is widely used in instrument casings, televisions, mobile phones, textile equipment, automobile parts and other fields.