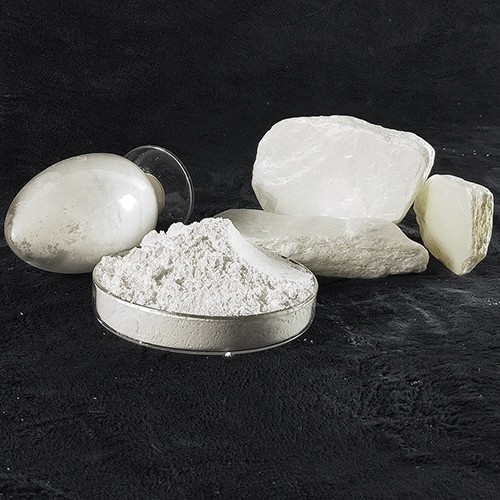

Introduction to the seven application areas of ultrafine talcum powder-4

Talc powder has the following advantages when used as a filler in the papermaking process:

(1) It is beneficial to improve the smoothness, opacity and printability of paper

(2) The wear value is small, which can extend the service life of the papermaking mesh

(3) It has stable chemical properties and is not only suitable for acidic papermaking, but can also be used in combination with calcium carbonate for neutral papermaking

(4) It has a good combination with the sizing agent to retain the sizing agent and prevent the penetration of printing ink

(5) It is lipophilic and can adsorb organic matter to keep the white water and pulp system clean. As a filler, it also has the effect of eliminating resin obstacles and helps to remove ink in the deinking of waste paper

(6) It has certain hydrophobicity and lubricity, which can reduce the water absorption of paper sheets, improve the smoothness and softness of paper sheets, and reduce operational obstacles such as calendering and finishing

(7) It is beneficial to remain in the paper sheets and reduce the fiber consumption per ton of paper products. Talc powder is used as a coating pigment, which has good fiber covering ability and printing effect. It can improve the whiteness, opacity, smoothness and printing gloss of coated paper, give the paper higher ink absorption, and improve the quality of gravure printing. Talc powder is also lubricating, and the coated paper made of it can obtain high finishing degree on the calender and reduce the amount of lubricant used in the coating. However, talc powder also has corresponding disadvantages due to its hydrophobicity: it is difficult to wet and disperse when preparing the coating, and the prepared coating has shear expansion, low retention rate, and is easy to cause paper to fall off. Therefore, some talc powder needs to be surface treated before use.

Due to the lipophilicity given to talc powder by its structural characteristics, the application of talc powder in pulping and papermaking can effectively control the viscosity of resin and anions. On the one hand, it can adsorb hydrophobic adhesive substances in the papermaking system, reduce the surface energy of anionic adhesives, and make them lose their unique viscosity, thereby inhibiting the adhesion, aggregation and deposition of adhesives; on the other hand, adhesives that have already aggregated can also adsorb talc powder, thereby reducing the viscosity of the adhesive surface and avoiding further aggregation and deposition.

In general, talc powder plays an important role in the papermaking industry with its unique hydrophobic properties. How to make good use of the characteristics of talc powder while maximizing its strengths and avoiding its weaknesses still needs to be explored.