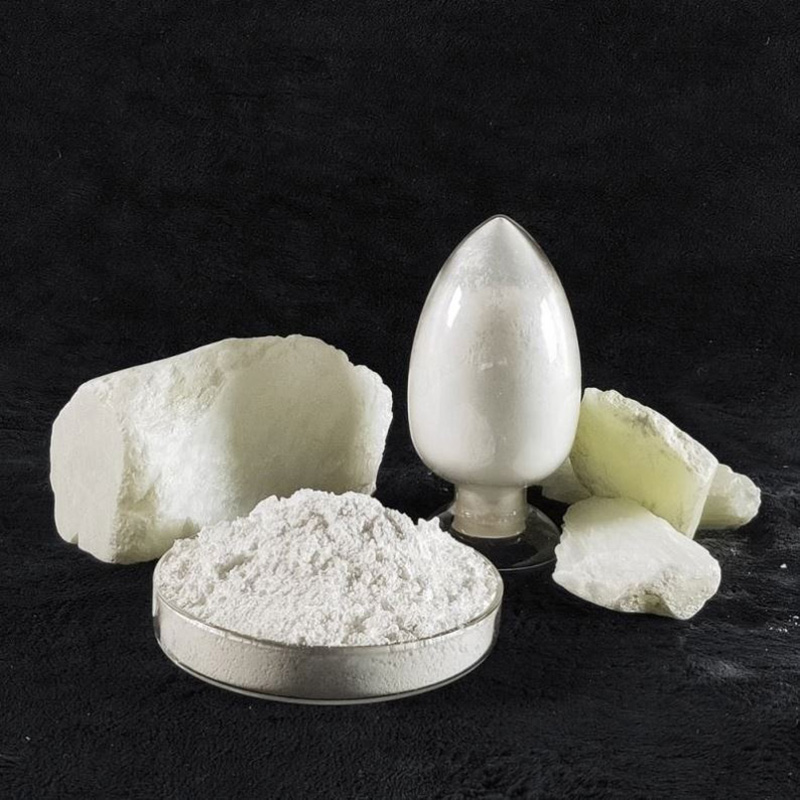

Introduction to the seven application areas of ultrafine talcum powder-3

Multiple applications of talc in the pharmaceutical industry

As a dispersant for volatile oils

Medicine Grade Talc Powder has a certain adsorption capacity, which can adsorb volatile oil on the surface of its particles and disperse it evenly, increasing the contact area between volatile oil and liquid medicine, thereby improving the solubility of volatile oil.

Powder coating applied to sugar-coated tablets

During the coating process of sugar-coated tablets, Medicine Grade Talc Powder can be used to coat the powder coating layer. It is best to choose white talc powder that passes through a 100-mesh sieve, and the usual dosage is 3% to 6%. Talc powder can not only effectively eliminate the edges and corners of tablets during coating, making it easier for coating operations, but can also improve the stability of sugar-coated tablets, thereby extending their storage and service life.

as lubricant

Talcum powder has a layered structure and is easily split into scales, so it is widely used as a lubricant to improve the compression moldability and fluidity of pharmaceutical powders. By filling the recessed areas on the surface of drug powder, Medicine Grade Talc Powder can reduce the friction between powders, thereby significantly improving the fluidity of drug powder and helping to improve preparation production efficiency.

Used as filter aid

Medicine Grade Talc Powder's chemical inertness and certain adsorption capacity make it an ideal filter aid. Medicine Grade Talc Powder activated at 115°C is added to the medicinal solution and can absorb a small amount of polysaccharides, mucus and gum impurities in the medicinal solution without destroying the active ingredients of the drug.

Various applications of Medicine Grade Talc Powder as pharmaceutical excipients

Used as a disintegrant for hydrophobic drugs

Medicine Grade Talc Powder is a hydrophilic substance. When added as an excipient to a drug, it can improve the overall hydrophilicity of the drug, making it easier for water to penetrate into the drug, thus accelerating the disintegration process of the drug. This characteristic makes talc an ideal disintegrant for hydrophobic drugs, which can effectively shorten the disintegration time of the drug and improve the rapid release of the drug effect.

Used as anti-sticking agent

Stickiness problems often occur during the coating process, such as slowed coating speed, prolonged production cycle, adhesion of pellets, reduced yield, damaged coating, etc., which not only affect the appearance of the drug, but may also change the release characteristics of the drug. Medicine Grade Talc Powder can be used as an anti-adhesive agent to reduce the adhesion between tablets during the coating process, optimize the coating operation, improve production efficiency, and ensure the stability of drug release.

Increase the critical relative humidity of drugs

Studies have shown that talc can significantly reduce the hygroscopicity of medications. For example, in the study on the hygroscopicity of total flavonoids of Ilex tomentosa, talcum powder showed significant improvement in the initial speed of moisture absorption, moisture absorption acceleration, equilibrium moisture absorption time and equilibrium moisture absorption amount. Medicine Grade Talc Powder not only reduces the equilibrium moisture absorption and moisture absorption acceleration of the drug, but also increases the critical relative humidity of the drug. The larger the dosage, the more significant the effect, thereby extending the stability and shelf life of the drug.