How to improve the heat resistance of plastics through materials such as talc-2

4. Improving heat resistance through blending modification

By mixing low heat-resistant resin with high heat-resistant resin, the heat resistance can be improved while maintaining the original other properties as much as possible.

For example:

ABS blended with PC: the heat deformation temperature is increased from 93°C to 125°C.

HDPE blended with 20% PC: the Vicat softening point is increased from 124°C to 146°C.

5. Improving heat resistance through cross-linking modification

Cross-linking technology is widely used in heat-resistant pipes and cable materials, and can enhance heat resistance through intermolecular cross-linking.

For example:

HDPE is cross-linked with silane: the heat deformation temperature is increased from 70°C to 90~110°C.

PVC is cross-linked: the heat deformation temperature is increased from 65°C to 105°C.

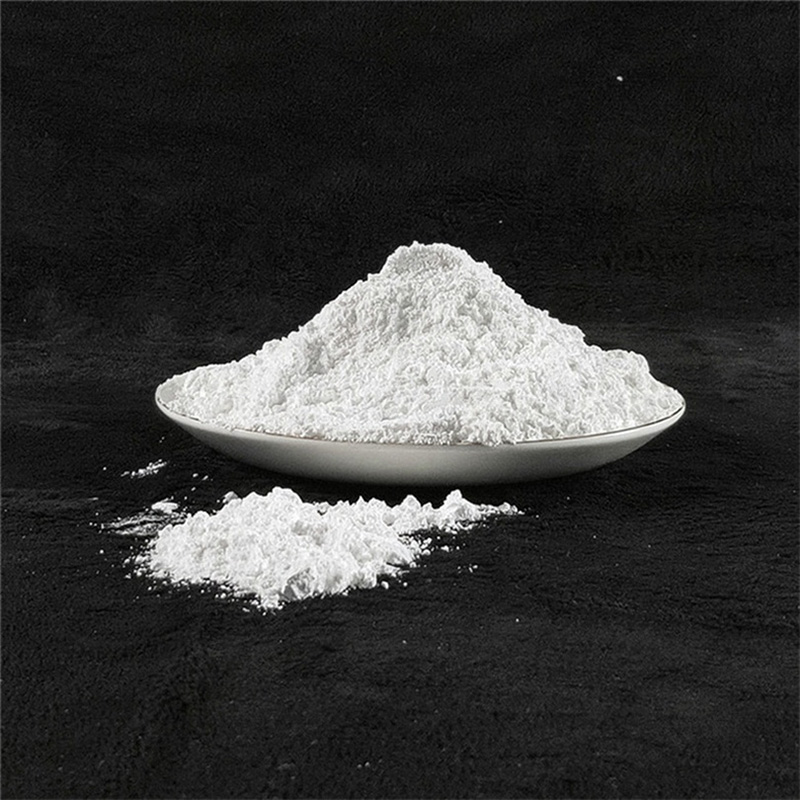

6. Application of talcum powder in heat-resistant modification of plastics

As a common inorganic filler, talcum powder is widely used in heat-resistant modification of plastics due to its excellent heat resistance and stability.

Characteristics of talcum powder

Talcum powder has small particle size, high whiteness, good heat resistance, strong compatibility with plastic matrix, and can effectively increase the heat deformation temperature of plastic.

Specific case

After PBT is filled with 30% talcum powder, the heat deformation temperature increases from 55°C to 150°C.

The addition of talcum powder to polymer materials can also improve the dimensional stability, mechanical strength and wear resistance of the product.

Conclusion

The heat resistance of plastics can be significantly improved through methods such as molecular structure modification, filling modification, reinforcement modification, blending modification and cross-linking modification. Among them, the application of inorganic fillers such as talcum powder has the advantages of low cost and obvious effect, and is one of the important ways to modify the heat resistance of plastics. In practical applications, the appropriate modification method should be selected according to the performance requirements of the plastic to optimize heat resistance and other physical properties.