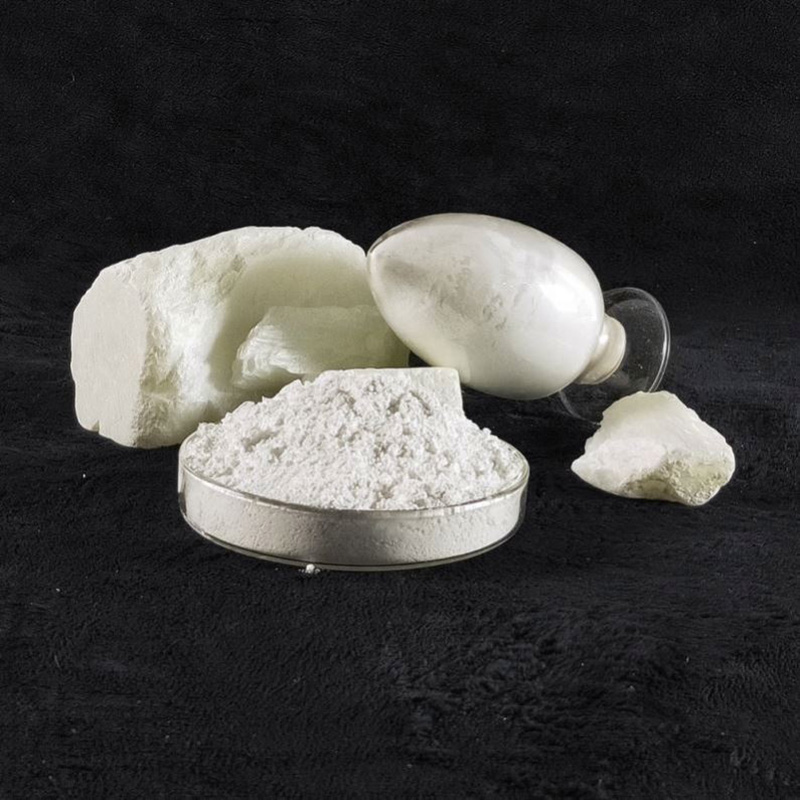

Do you know the four "degrees" of talc powder?-4

Fineness

Micronization is the development trend of talcum powder products. The finer the product, the better the reinforcing effect. At the same time, the surface energy of the particles increases, it is easy to agglomerate, difficult to disperse, and expensive. Therefore, we need to choose products with appropriate fineness according to our own technical level and actual needs, not the finer the better.

The evaluation of the particle size of a talcum powder product cannot be based on the average fineness alone. There are at least two indicators to evaluate the quality of a product: D50 and D100 (or D98).

As the products become finer and finer, people have higher requirements for the microscopic shape and particle size distribution of fine talcum powder after crushing. The main indicator for evaluating particle size distribution has shifted from D50 to D97, D98 and now D100. At the same time, the reproducibility of particle size distribution is more stringent. When evaluating a product, its average particle size must not only meet the requirements, but more importantly, the particle size distribution should be as narrow as possible, with as few large particles as possible.

The product should strive to achieve the same particle size distribution for each batch, which is very difficult in production practice. In high-end talcum powder products, controlling particle size distribution, especially the number of coarse particles, is a very critical technology, which requires not only high-efficiency, high-precision, and reliable grading equipment, but also rich operating experience and equipment maintenance capabilities. Particle size distribution can be measured by a particle size distribution instrument, including laser method and sedimentation method. However, screening method is mostly used to detect the number of coarse particles in production practice.

It is worth noting that talcum powder has a large specific surface area and a small volume density due to its own flaky structure. The volume density of 325 mesh talcum powder is 0.8-0.9g/cm3, while 1250 mesh talcum powder drops to 0.25-0.3g/cm3, and 4000 mesh is only about 0.12g/cm3. This causes serious dust pollution during use, difficulty in mixing, increased costs, and reduced yields. Moreover, the freight cost of long-distance supply is quite high.

In response to the above problems, we have successfully developed talcum powder compression technology and granulation technology. The apparent density of talcum powder is greatly improved through compression. For example, the apparent density of 1250 mesh product reaches 0.8-0.9g/cm3. Granulation is to convert powdered talcum powder into granules, further increase the apparent density, achieve dust-free, reduce transportation and packaging costs, and facilitate storage.