Application of talc powder and silica in polyethylene composites for automotive engineering

Due to its light quality, excellent physical and chemical properties, abundant raw materials and easy processing, polyethylene has become a common variety of automotive plastics. However, the poor thermal aging, wear resistance and impact resistance of polyethylene limit its applicability in automotive engineering application materials.

The formulation of polyethylene composite material

| Filler content(5%) | ||

| Sample ID | SiO2 | Modified Talc Powder |

0 | 0 | 100 |

| 1 | 10 | 90 |

| 2 | 20 | 80 |

| 3 | 30 | 70 |

| 4 | 40 | 60 |

| 5 | 50 | 50 |

| 6 | 60 | 40 |

| 7 | 70 | 30 |

| 8 | 80 | 20 |

| 9 | 90 | 10 |

| 10 | 100 | 0 |

(1) When different contents of silica and talc are combined with polyethylene, there are great differences in the improvement of its mechanical properties. Considering different performance indexes, it can be seen that the polyethylene composite with 50% silica has the best mechanical properties among the composites.

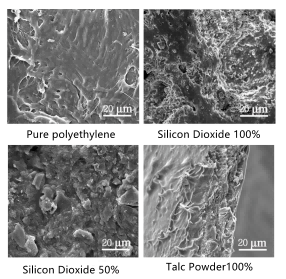

SEM IMAGES OF DIFFERENT POLYETHYLENE COMPOSITES

As a kind of lamellar structure and its larger diameter to thickness ratio, talc can effectively prevent the crack propagation of polyethylene, make the stress concentration and increase the tensile strength. However, when the content of silica is high, some particles will agglomerate and affect the mechanical properties of PE composites. Therefore, the enhancement effect of higher content of silica on PE is not obvious.

(2) Compared with pure polyethylene, the combined action of silica and talc can effectively improve its thermal stability. This is due to the small particle size and high surface energy of silica, when it is mixed with the appropriate content of talc, can adsorb on its surface to form a composite structure. These composite structures can form strong interfacial interactions with the macromolecular chains of polyethylene to increase its thermal stability.

(3) Compared with the performance index of a certain automobile brand material, the performance index of the prepared POLYETHYLENE composite has a certain excellent, and compared with the pure polyethylene has better aging resistance, indicating that it can be used in automotive engineering materials.