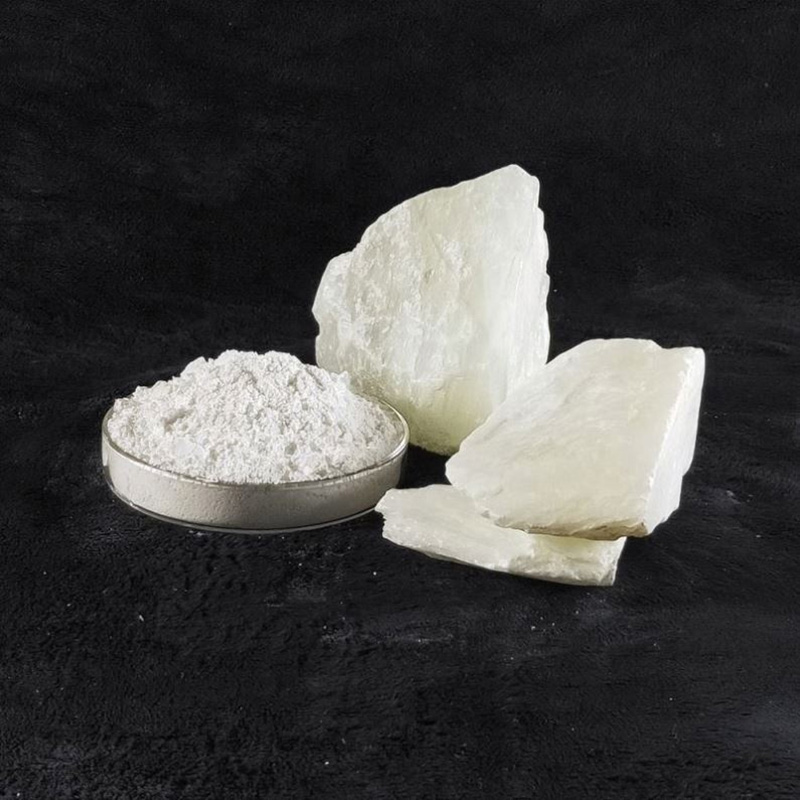

Advantages and disadvantages of talcum powder and application precautions

Advantages:

Talc powder is soft and easy to disperse, which can improve the suspension and stability of the paint.

Improve the filling performance of the paint, increase the solid content, and reduce the production cost.

Improve the physical properties of the paint, such as transparency, fluidity and construction performance.

Disadvantages:

High oil absorption: In occasions where the oil absorption requirement is low, it needs to be used in combination with fillers with low oil absorption (such as barite powder).

Poor wear resistance: For coatings that require high wear resistance, other fillers need to be added to compensate.

Limited weather resistance: Talc powder containing non-metallic mineral impurities may react with acidic substances (such as acid rain), so it is not suitable for high weather resistance exterior coatings.

Application restrictions:

The whiteness of talcum powder is greatly affected by impurities, so it should not be used in occasions where the color brightness requirement is high.

Talc powder has a matting property, so it is not suitable for high gloss coatings.

Dosage and selection of talcum powder

The amount of talcum powder added to the coating is usually 5%-40%, and the specific ratio needs to be determined through experiments according to the product performance requirements. In practical applications, according to the formulation requirements, cost considerations and customer requirements, the appropriate type of talcum powder (particle size and modification method) is reasonably selected to produce coating products that meet market demand.

In summary, talcum powder has important value in the coating industry with its diverse performance and wide applicability. However, due to the different performance requirements of coatings, it is impossible to rely on a single filler. It is necessary to combine the advantages of multiple fillers and optimize the formula design to meet different usage scenarios and customer needs.